Industrial Aluminum Foil

- Alloy: 8011, 1100, 1235

- Thickness: 0.009-0.2mm or Customized

- Width: 200-1400mm or Customized

- Type: roll

- Service: 7/24 work for you any time

- MOQ: 300-500 KG

Description

| product parameters

| Product | Aluminum foil for lithium batteries |

| Temper | Soft |

| Type | Roll |

| Model Number | 8011/1100/1235 |

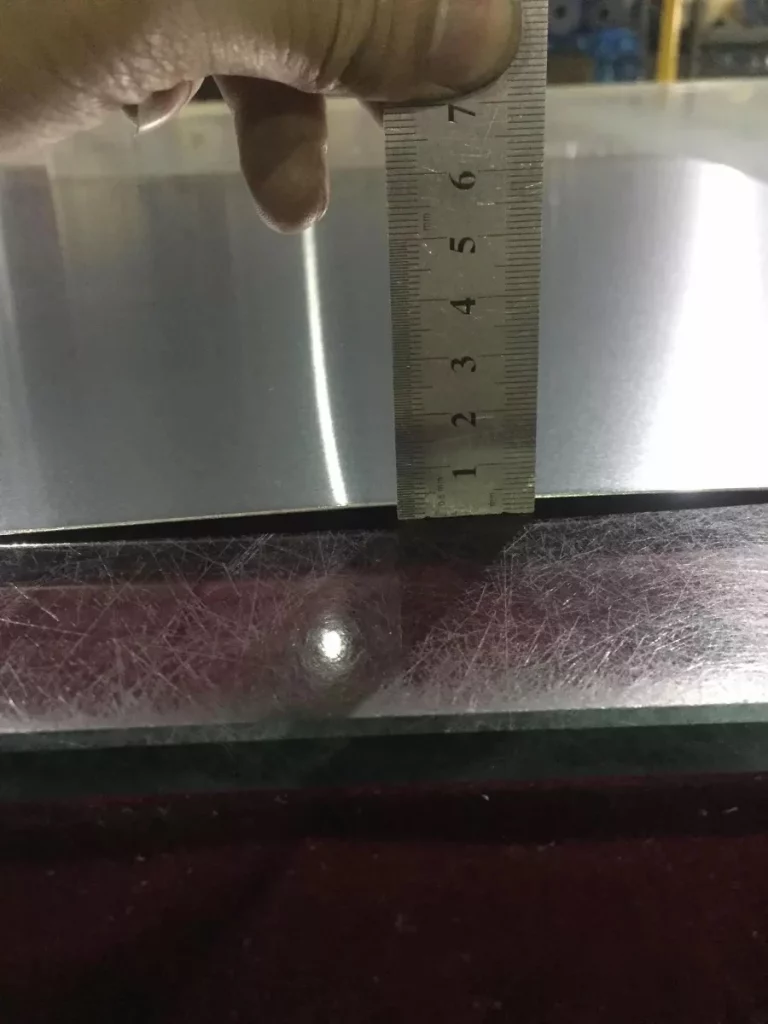

| Thickness | 0.009-0.2mm |

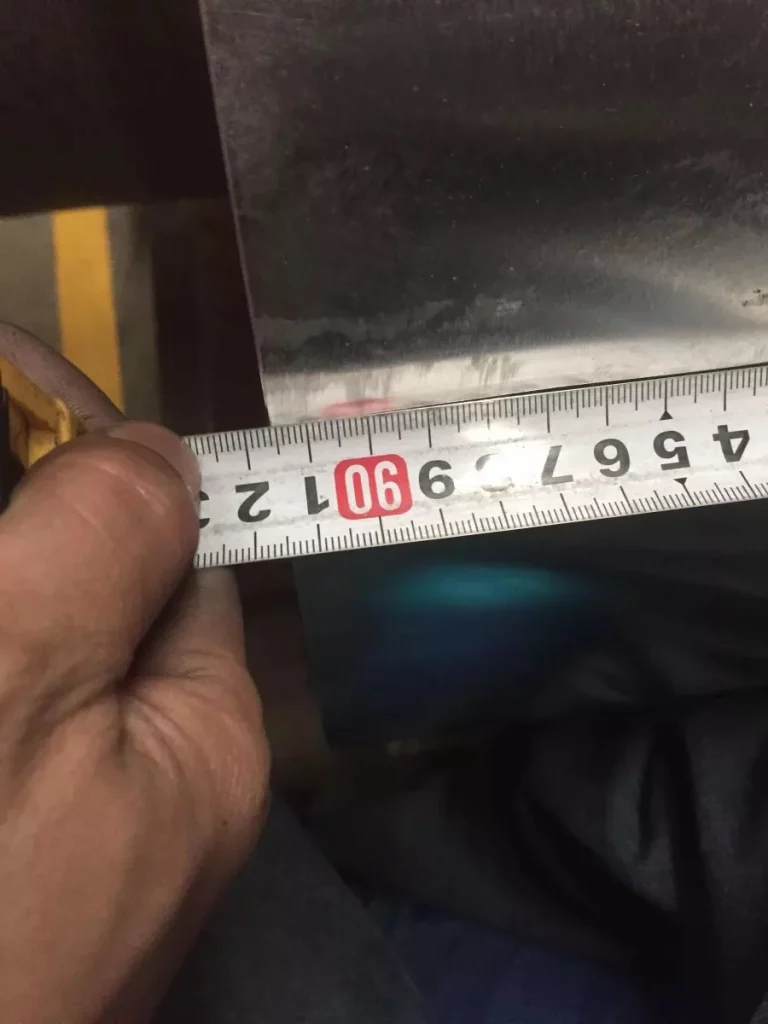

| Width | 200-1400mm |

| Packing | Standard export packaging options include wooden boxes, or as specified |

| Payment | T/T, L/C 100% at sight |

| MOQ | 300-500 KG, special require need discuss |

| Delivery time | 1-3 days for spot goods, 10-15 days for normal size,15-25 days for special size |

| Surface Quality | Be free from Oil Stains, Dents, Inclusion, Scratches, Stains, Oxide Discoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defects that will interfere with use. |

| Our Advantages

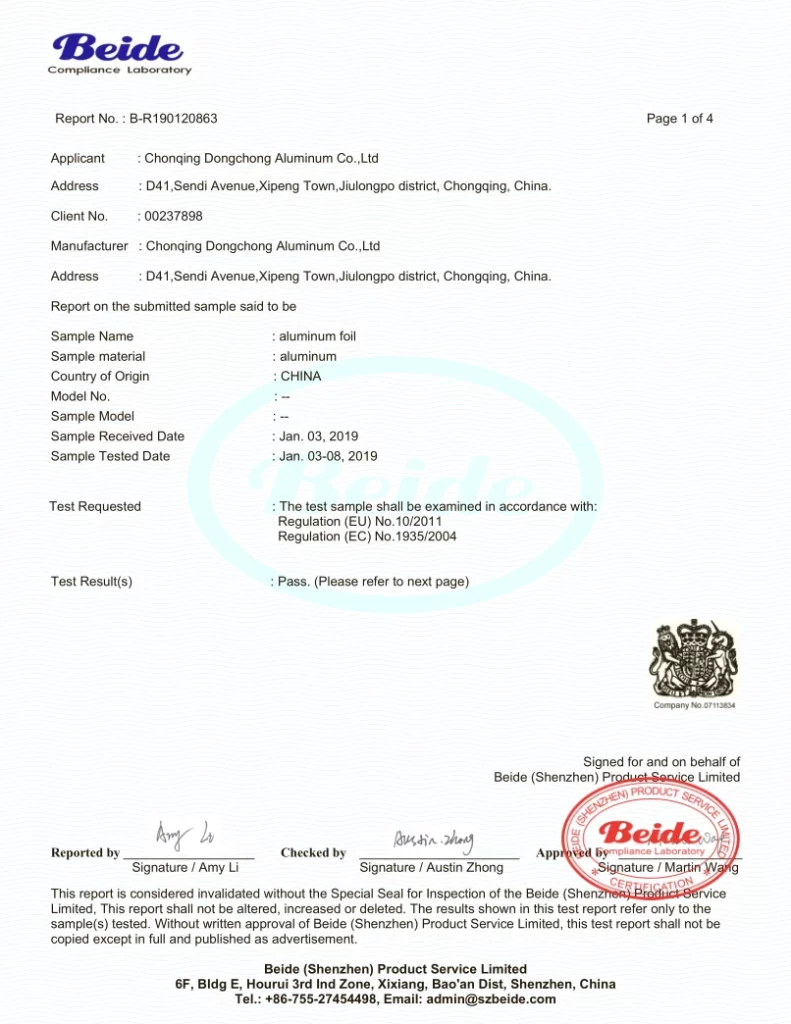

- High Purity and Stability: We provide aluminum foil with a purity of over 98%, ensuring the internal stability and safety of your products.

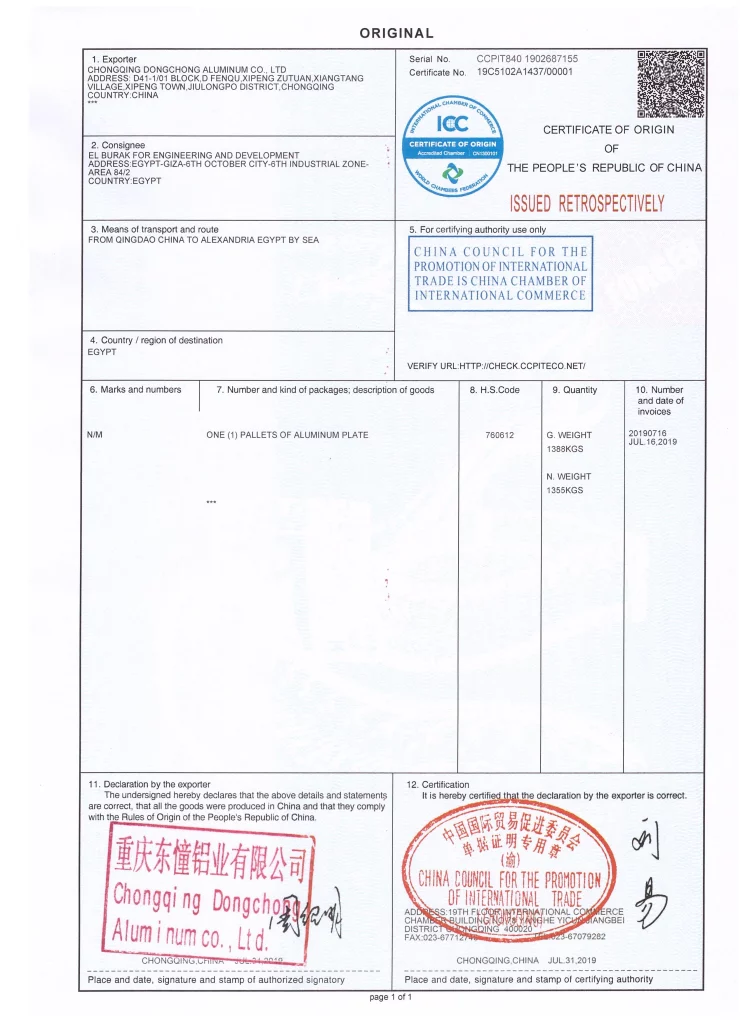

- Cost-effective: With abundant aluminum material resources, our factory-direct prices are low, allowing you to effectively control procurement costs.

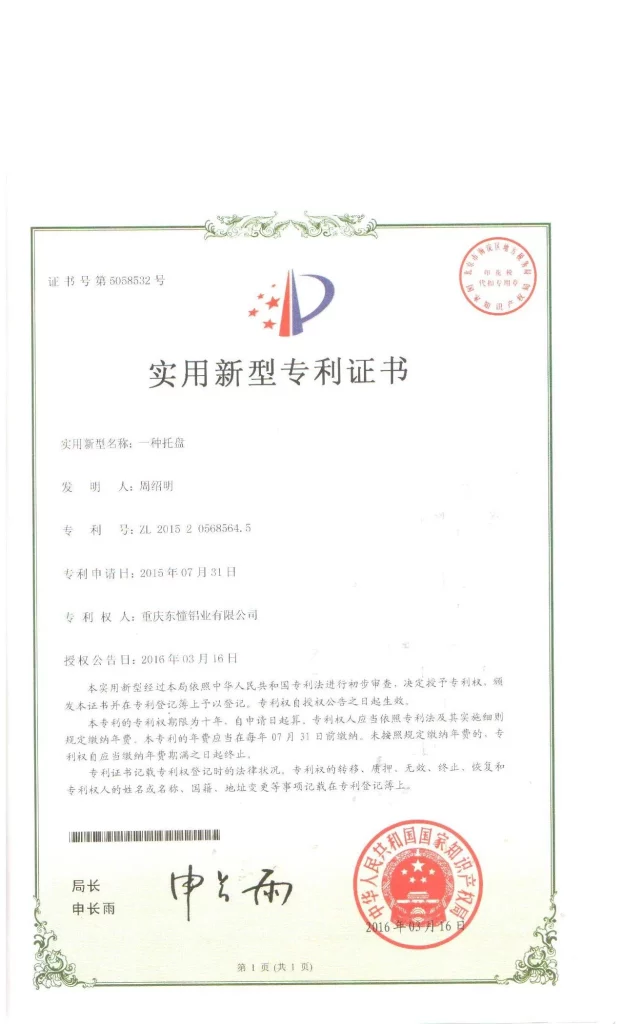

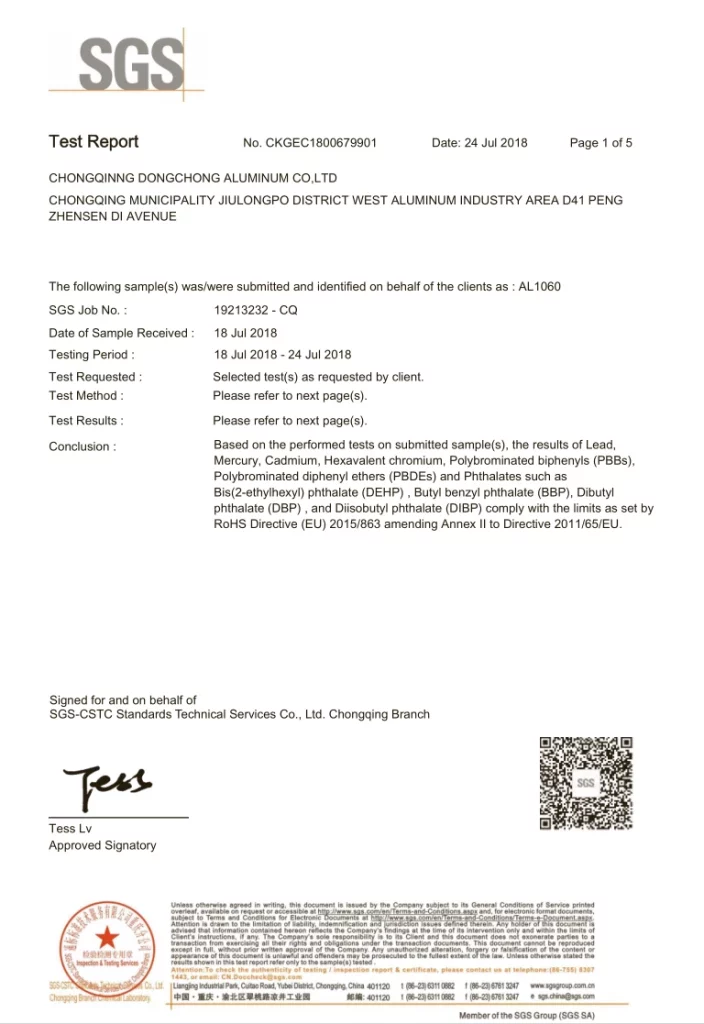

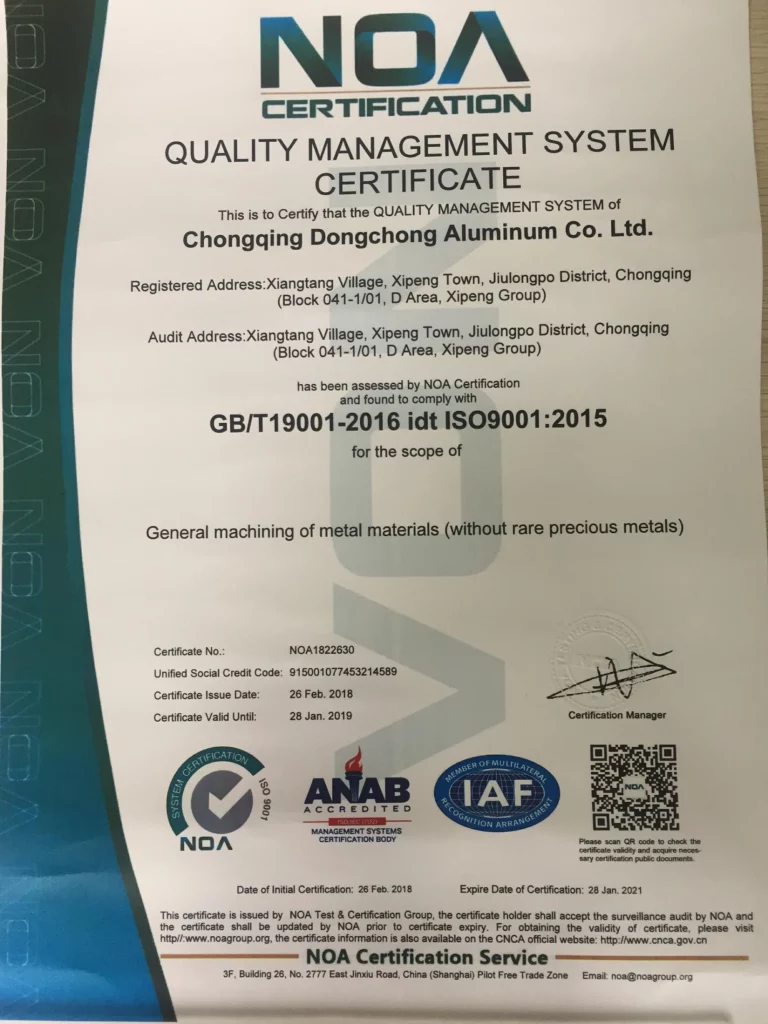

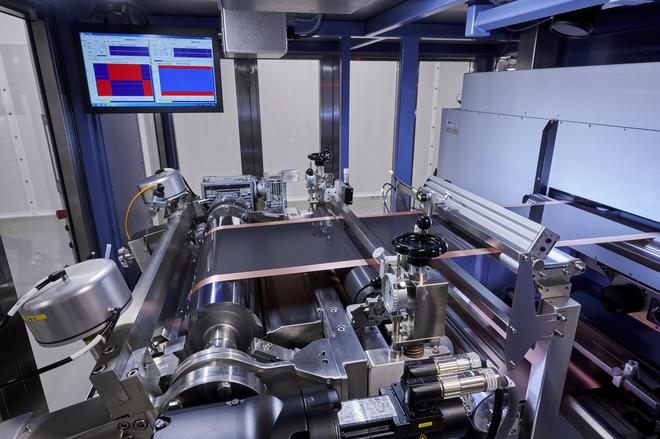

- Mature Technology: Our aluminum foil production process is mature, ensuring the consistency and reliability of product quality. We strictly control the cleanliness of aluminum raw materials, especially the proportion of recycled materials, to ensure the high purity and quality of the aluminum foil.

- Ample Inventory: As a manufacturer with our own factory, we have ample stock of standard models and sizes, ready for immediate shipment.

- Customization Accepted: Our technicians, with more than 10 years of production experience, can fully meet your special requirements and provide customized solutions for you.

- Rapid Response Mechanism: We have established an efficient customer service process that ensures a swift reaction from the moment we receive a client’s request.

- Professional Customer Service Team: We have a team of professional customer service representatives who have undergone comprehensive training and are capable of promptly addressing client inquiries and issues.

- Around-the-Clock Service: We offer round-the-clock customer support, ensuring that clients receive timely service regardless of the time of day, on weekdays or holidays.

- Multi-Channel Service Access: Clients can contact us through various channels, including phone and email, ensuring the convenience of communication.

- Regular Follow-Ups: We conduct regular check-ins with our clients to proactively understand their product usage and needs, and to promptly resolve any issues that arise during the process.

- Post-Sales Technical Support: We provide a professional technical support team to assist clients with technical issues they may encounter while using our products.

- Rapid Feedback Processing: We commit to responding quickly and taking action within a specified time frame for all client feedback and suggestions.

- Flexible After-Sales Policy: We offer a flexible after-sales policy, and in the event that a product has quality issues or does not meet client requirements, we provide return and exchange services to ensure the rights of our clients are protected.

| Application of Industrial Aluminum Foil

The encapsulation material for flexible packaging lithium batteries

Aluminum plastic film, composed of aluminum foil and other materials, is a key encapsulation material for flexible packaging lithium batteries due to its lightweight and thin characteristics, which can significantly enhance the energy density of the batteries. The aluminum foil layer plays a major barrier role in the aluminum plastic film, with complete light-blocking capability, and very low water vapor transmission rate and oxygen transmission rate, making it an excellent material for water and oxygen barrier.

Research and development of anode materials

Through electrochemical prelithiation technology, lithium is supplemented on the aluminum foil to achieve high-performance elemental foil anodes. This technology can prevent severe stress concentration during the alloying process, avoiding perforation and pulverization of the foil, enabling commercial aluminum foil to successfully serve as a single-material anode.

Used as the current collector for the cathode

It is widely used due to its high electrical conductivity, good flexibility, and low weight. In addition, aluminum foil has high chemical stability and corrosion resistance, effectively resisting the dissolution, absorption, swelling, and permeation of the electrolyte.