8011 Mill Finish Aluminum Coil

- Alloy: 1050, 1060, 1100, 1070, 3003, 3004, 3105, 5052, 5054, 5083, 6061, 6063, 6062, 7075, 8011

- Temper: H12, H14, H16, H24, H26, H32, O, H112, T3, T6, T4, T651,etc.

- Surface: Mill finish, color coated, embossed, engraving, checkered

- Thickness: 0.1-6mm

- Width: 10-2600mm

- Inner core: 76/150/405/505mm

- MOQ: 300-500 KG

Description

Mill Finish Aluminum Coil refers to aluminum that has been rolled into coils and has a surface finish as it comes straight from the mill. It typically has a smooth, matte appearance with a natural aluminum color, without any additional treatment or coating.

| 8081 Mill Finish Aluminum Coil parameters

| Product | Aluminum Coil |

| Temper | H12, H14, H16, H24, H26, H32, O, H112, T3, T6, T4, T651, etc. |

| Surface | Mill finish |

| Thickness | 0.1-6mm |

| Width | 10-2600mm |

| Inner core | 76/150/405/505mm |

| Packing | Standard export packaging options include wooden boxes, or as specified |

| Payment | T/T, L/C 100% at sight |

| MOQ | normally 5 tons, special require need discuss |

| Delivery time | 1-3 days for spot goods, 10-15 days for normal size,15-25 days for special size |

| Surface Quality | Be free from Oil Stains, Dents, Inclusion, Scratches, Stains, Oxide Discoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defects that will interfere with use. |

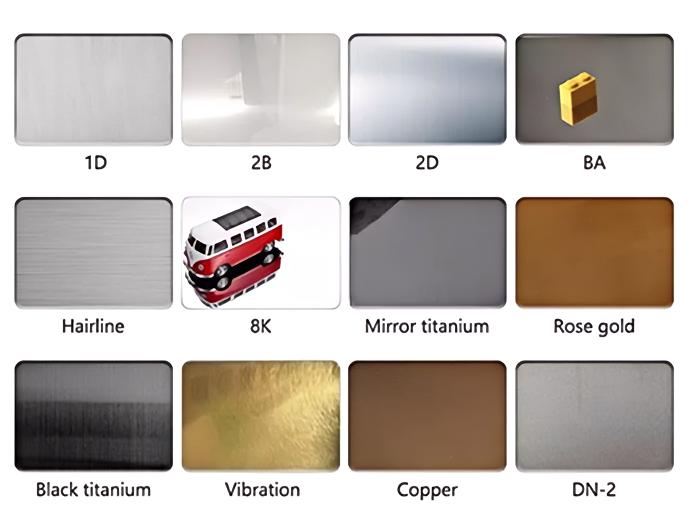

| Aluminum Coil Surface Treatment

| Advantages of Mill Finish Aluminum Coil

- Cost-Effective: Since it requires minimal processing after being rolled into coils, Mill Finish Aluminum is often more cost-effective than coils that have undergone additional surface treatments.

- Versatility: This type of aluminum coil is available in various alloys, each with its own set of properties, making it suitable for a wide range of applications, from construction to manufacturing.

- Ease of Processing: Mill Finish Aluminum Coil is easy to cut, shape, and form, making it ideal for fabrication processes such as bending, stamping, and deep drawing.

- Natural Corrosion Resistance: Aluminum has a natural oxide layer that provides some protection against corrosion. Mill Finish Aluminum Coil retains this oxide layer, offering inherent resistance to many environmental conditions.

- Consistent Quality: Produced in a controlled manufacturing environment, Mill Finish Aluminum Coil offers consistent thickness and width, which is essential for precision work.

- Recyclability: Aluminum is one of the most recyclable materials, and Mill Finish Coil is no exception. It can be re-melted and re-rolled without significant loss of quality, contributing to sustainability efforts.

- Aesthetic Appeal: The natural silver color of Mill Finish Aluminum can be desirable for applications where the raw material’s appearance is preferred.

- Ready for Further Processing: Mill Finish Aluminum Coil is an excellent base material for further manufacturing processes such as anodizing, painting, or coating, which can enhance its appearance and performance for specific uses.

- Availability: Mill Finish Aluminum Coil is widely available in the market, making it easy for manufacturers to source the material they need.

- Strength-to-Weight Ratio: Aluminum is known for its high strength-to-weight ratio, which is beneficial for applications where weight is a critical factor.

- Thermal Conductivity: Aluminum’s good thermal conductivity can be advantageous in applications where heat transfer is important, such as in heat exchangers or cooking utensils.

- Non-Magnetic: Aluminum is non-magnetic, which is a beneficial property in environments where magnetic fields could interfere with the performance of equipment.

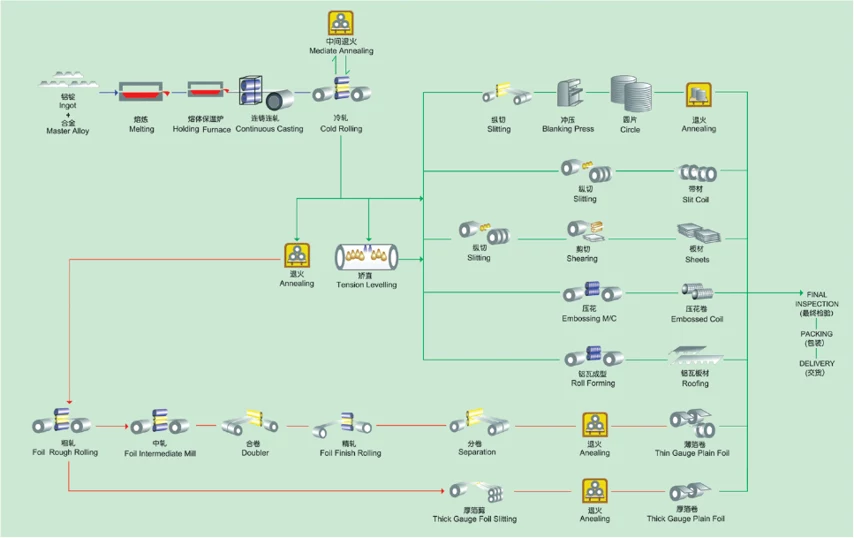

| Process flow diagram

| Packaging and Shipping

| FAQ

Q1. What is the minimum order quantity?

MOQ: 1 ton. For special needs, please contact our experts for consultation.

Q2. What is your terms of payment?

T/T 30% deposit in advance; the balance paid should be paid according to the copy of B/L.

Q3. How about your delivery time?

Generally, it will take 15 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings.

Q5. Why can I trust you and place order with you?

We are manufacture and supplier of aluminum composite panel in china with over 22 year’s experience.We keep fastest delivery. Since we have perfect production equipment.

Q6. How can I get the best quote?

Please provide DongChong’s expert team with the product specifications, dimensions, purchase quantity, delivery address, contact information and other information you need, and our experts will provide you with one-to-one service.