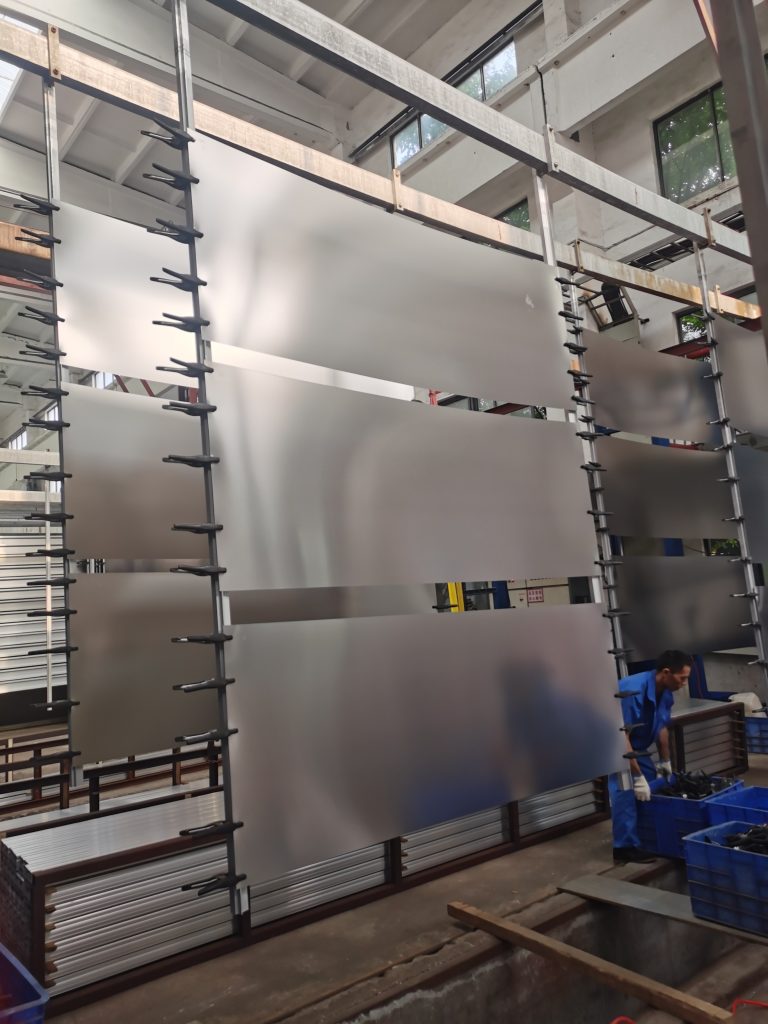

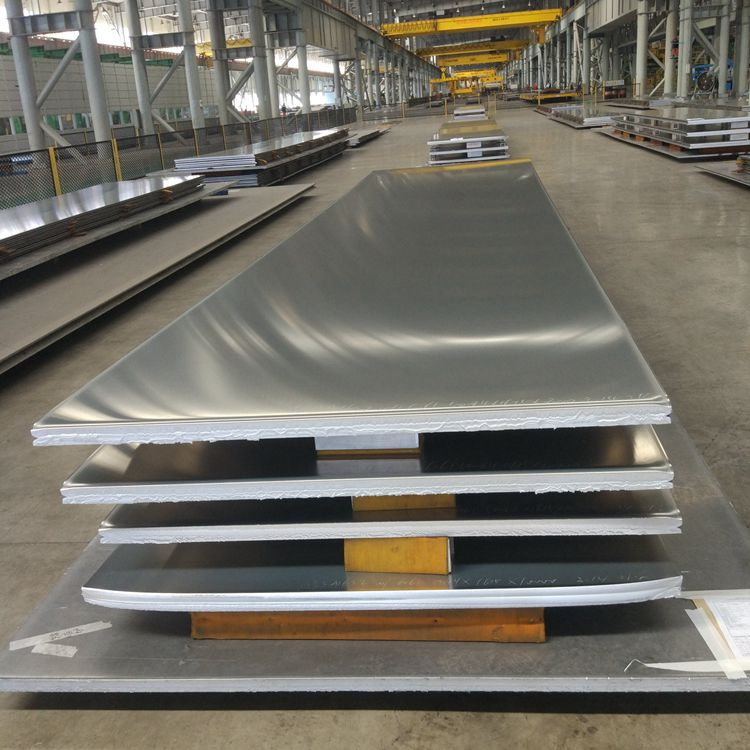

6063 Anodized Aluminum Plate

- Brand: DongChong

- Alloy: 6063

- Annual output: 600,000 tons

- Surface: Anodized

- Thickness: 0.2-200mm

- Width:10-2600mm

- MOQ: 1 Ton

- Delivery time: 7-15 days within stock, special sizes require consultation

Description

| Specifications

| Product | Aluminum Plate | |||||

| Alloy | 6063 | |||||

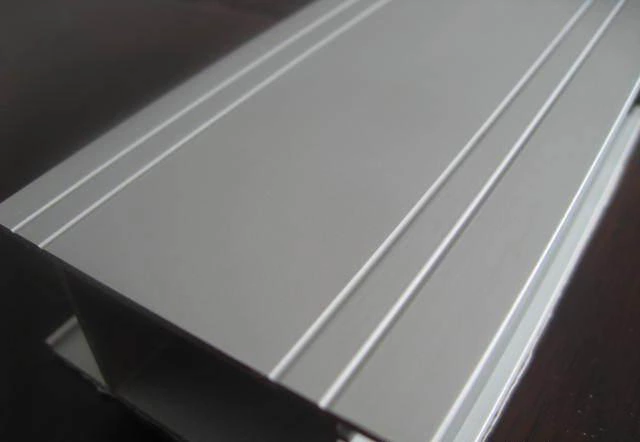

| Surface | Anodized | |||||

| Thickness | 0.2-300mm or customized as required | |||||

| Width | 10-3500mm or customized as required | |||||

| Length | 2000mm, 2440mm, 6000mm or customized as required | |||||

| Temper | O, H111, H112, H14, H18, H19, H22, H24, H26, H28, etc. | |||||

| Standards | ASTM B209,JIS H4000 and etc. | |||||

| Packing | Standard export packaging options include wooden boxes, or as specified | |||||

| Tolerance | ±1% | |||||

| Payment | T/T, 100%L/C, Western Union | |||||

| Definition and Advantages of Anodizing

Definition

The process of using aluminum or aluminum alloy products as anodes, placing them in an electrolyte solution for energization treatment, and forming an aluminum oxide film on the surface by electrolysis is called anodization of aluminum and aluminum alloys.

Advantages

After anodizing, the surface of the aluminum can produce a few microns-hundreds of microns of oxide film. Compared with the natural oxide film of aluminum alloy, its corrosion resistance, wear resistance and decorative properties have been significantly improved and improved. In fact, the direct current sulfuric acid anodic oxidation method is the most common application, because it is suitable for aluminum and most Anodizing of aluminum alloy; thicker film, hard and wear-resistant, better corrosion resistance after sealing; film colorless and transparent, strong adsorption capacity, easy to color; lower processing voltage, less power consumption; The treatment process does not need to change the voltage cycle, which is conducive to continuous production and practical operation automation; sulfuric acid is less harmful to human body than chromic acid, wide supply, low price and other advantages. The aluminum or its alloy of the anode is oxidized, and a thin layer of alumina is formed on the surface, with a thickness of 5-30 microns, and the hard anodized film can reach 25-150 microns.