6062 Aluminum Plate

- Product: Aluminum Sheet/Plate

- Alloy: 1050, 1060, 1100, 1070, 3003, 3004, 3105, 5052, 5754, 5083, 6061, 6063, 6062, 7075, 8011

- Temper: H12, H14, H16, H24, H26, H32, O, H112, T3, T6, T4, T651, etc.

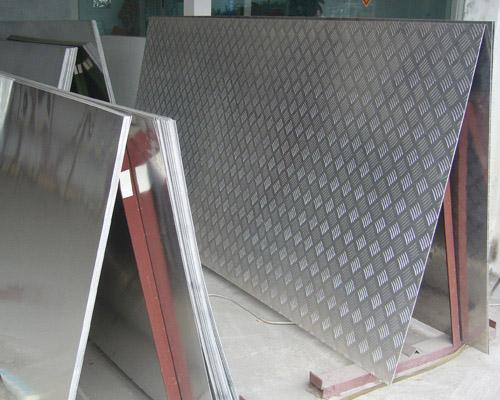

- Surface: Mill finish, color coated, embossed, engraving, checkered

- Thickness: 0.2-200mm

- Width:10-2600mm

Description

6062 aluminum plate is a high-strength, corrosion-resistant alloy used extensively in the aerospace industry to manufacture structural components. This alloy is known for its excellent mechanical properties, including a tensile strength of 280-330 MPa, a yield strength of 240-300 MPa, and an elongation of 12-16%. It is easily formed, machined, and welded, with a density of 2.70 g/cc and a melting point range of 620-650 °C. Our plates are available in a variety of tempers, such as T4, T6, and T651, each tailored for specific applications. Choose our 6062 aluminum plate, a material that combines strength, corrosion resistance, and machinability, backed by our mill expertise and global supply capabilities.

| 6062 Aluminum Plate Parameters

| Product | 6062 Mill Finish Aluminum Plate |

| Temper | H12, H14, H16, H24, H26, H32,O, H112, T3, T6, T4, T651, ect. |

| Surface | Mill finish, color coated, embossed, engraving, checkered |

| Thickness | 0.2-200mm, or customize |

| Width | 10-2,600mm, or customize |

| Length | 100-100,000mm, or customize |

| Packing | Standard export packaging options include wooden boxes, or as specified |

| Payment | T/T, L/C 100% at sight |

| MOQ | Normally 5 tons, special require need discuss |

| Delivery time | 1-3 days for spot goods, 10-15 days for normal size, 15-25 days for special size |

| Chemical Composition of 6062 Aluminum Plate

| Aolly | AI | Mg | Mn | Si | Fe | Cu | Ti | Zn | Cr | Others | |

| 6062 | Each | Total | |||||||||

| remainder | 0.80 – 1.20% | 0.15% | 0.40 – 0.80% | 0.70% | 0.15 – 0.40% | 0.15% | 0.25% | 0.10% | 0.05% | 0.15% | |

| Advantages of 6062 Aluminum Plate

- Automotive Sector: It is used in the manufacturing of various automotive components due to its strength and corrosion resistance, contributing to the lightweight construction of vehicles 79.

- Aerospace Industry: Known for its good mechanical properties and response to age-hardening heat treatment, 6062 alloy is used in aerospace applications where such characteristics are beneficial 76.

- Architectural Extrusions: The alloy is ideal for extrusions used in the construction of windows, doors, and other architectural elements that require both aesthetics and strength 79.

- Marine Applications: Given its high resistance to saltwater corrosion, 6062 aluminum plate is suitable for marine environments, such as in the construction of boats and ship components 76.

- Structural Components: It is used in general structural applications and high-pressure applications where high strength-to-weight ratio is needed 80.

- Manufacturing of Machinery: The alloy’s good machinability makes it a popular choice for manufacturing various machinery parts that require precision and durability 81.

- Heat Sinks: Due to its excellent thermal conductivity, 6062 aluminum is often used in the production of heat sinks for electronic devices and machinery that require efficient heat dissipation 79.

- Transportation Infrastructure: It is used in the construction of bridges, trusses, cranes, and other heavy-duty structures that demand high strength and durability 80.

- Industrial Equipment: The alloy’s properties make it suitable for use in industrial equipment and machinery where high performance and resistance to wear are required 76.

- Custom Fabrication: The alloy’s workability allows it to be fabricated into custom parts and components for specialized applications 79.

| Why Choose Us

- Innovative Custom Formulations: We don’t just offer standard aluminum products; we specialize in developing custom aluminum alloys tailored to specific industry needs, providing a solution that no other supplier can match.

- Sustainability Leadership: Our production processes are designed with sustainability in mind, from energy-efficient manufacturing to the use of recycled materials, positioning us as an industry leader in eco-friendly aluminum products.

- Exclusive Technology: We utilize proprietary technology that enhances the properties of our aluminum products, such as increased strength-to-weight ratios or unique surface treatments that offer superior resistance to environmental factors.

- Expert Consultation: Our team of experts provides unparalleled consultation services, working closely with customers to understand their unique challenges and offering tailored solutions that are unmatched in the market.

- Integrated Supply Chain Solutions: We offer a seamless, integrated supply chain solution that includes everything from raw material sourcing to finished product delivery, ensuring a level of convenience and efficiency that is unique in the industry.

- Advanced R&D Capabilities: With a state-of-the-art research and development facility, we are at the forefront of aluminum technology, constantly pushing the boundaries of what’s possible with our materials.

- Patented Processes: We have patented processes that give our aluminum products a distinct edge in terms of quality, performance, and applications, which cannot be replicated by competitors.

- Strategic Global Partnerships: Our strategic partnerships with key industry players provide customers with access to a network of resources and expertise that is unique to our company.

- Guaranteed Performance: We offer a performance guarantee on our aluminum products, ensuring customers that our materials will meet or exceed their expectations in real-world applications.

- Cultural Alignment and Ethical Practices: Our company operates with a strong ethical code and a culture that aligns with our customers’ values, building trust and a partnership that goes beyond mere transactions.

- Post-Sale Support and Education: We provide ongoing support and educational resources to help customers maximize the performance of our aluminum products, ensuring they get the most value from their investment.

- Exclusive Access to Niche Markets: We have established channels into niche markets that other suppliers cannot access, offering our customers unique opportunities for growth and expansion.

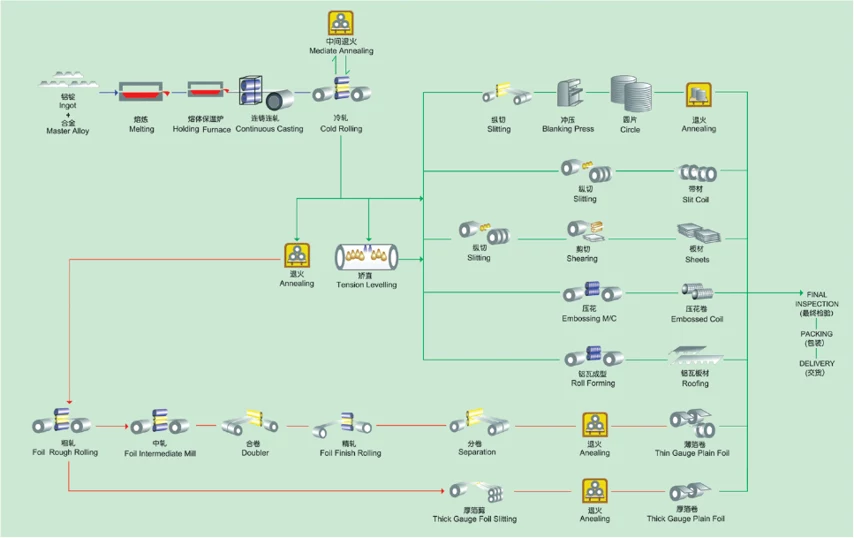

| process flow diagram

| 8011 Mill Finish Aluminum Plate Production Flow Chart

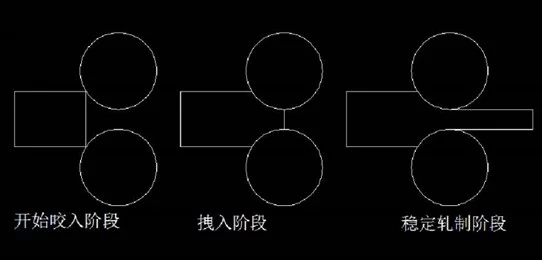

Hot-rolling

Smelting–standing–casting–fire–hot-rolling–cold-rolling –finished product annealing-packing

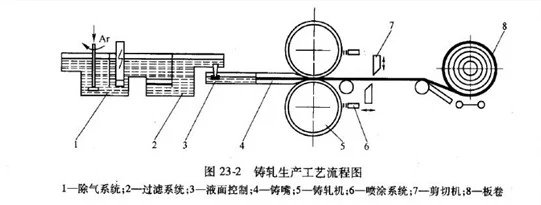

Cast-rolling

Smelting– standing — cast-rolling– cold-rolling– finished product annealing– packing

Casting

The purpose is to manufacture casting components that meet the requirements for a high purity alloy melt and create favorable conditions for casting various shapes.

Several key parameters in the casting process include:

- During the casting process, workers need to continuously add Al-Ti-B wire to refine the grain.

- The temperature generally needs to be set at 1050°C when smelting, with the material’s temperature under constant monitoring, and the metal temperature should be controlled to be less than 770°C.

- At around 735°C, workers need to perform slag operations; this temperature is favorable for the separation of slag from the liquid.

- Generally, two refining processes are required: one using a solid refining agent and the other using a gas refining method.

- After approximately 30 minutes to 1 hour of inert gas purging, workers need to cast in a timely manner; otherwise, re-refining may be necessary.

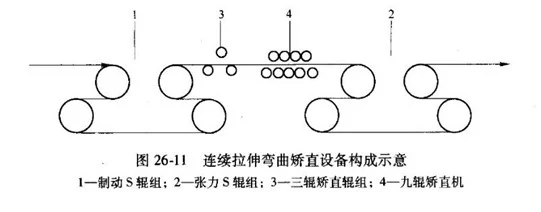

Tension Lever

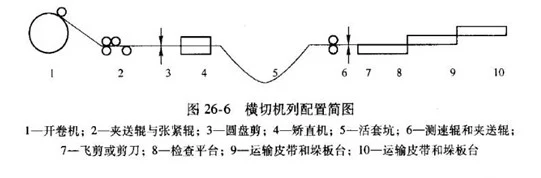

Slitting Mill

Cross Cutting Mill

Packing