3004 Aluminum Plate

- Product: Aluminum Sheet/Plate

- Alloy: 1050, 1060, 1100, 1070, 3003, 3004, 3105, 5052, 5754, 5083, 6061, 6063, 6062, 7075, 8011

- Temper: H12, H14, H16, H24, H26, H32, O, H112, T3, T6, T4, T651, etc.

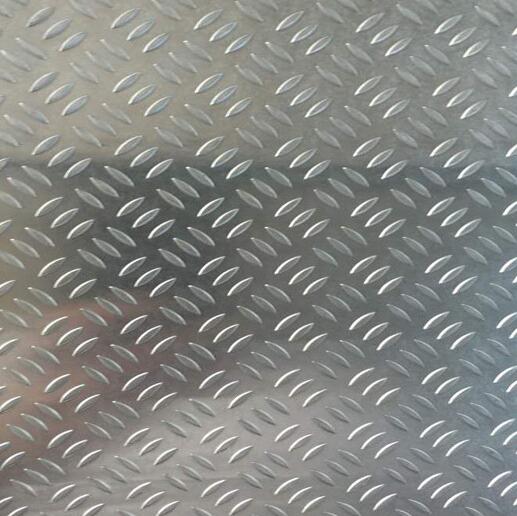

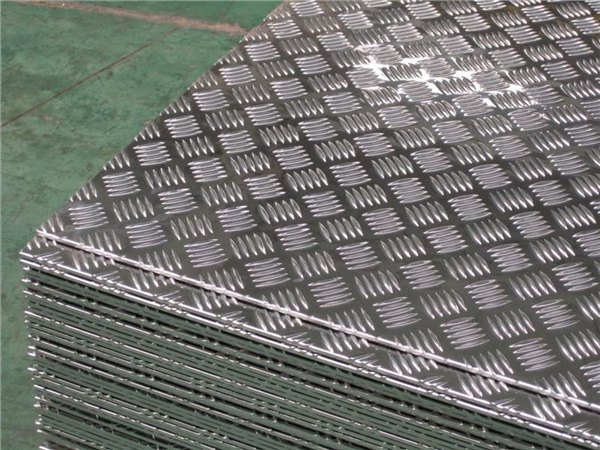

- Surface: Mill finish, color coated, embossed, engraving, checkered

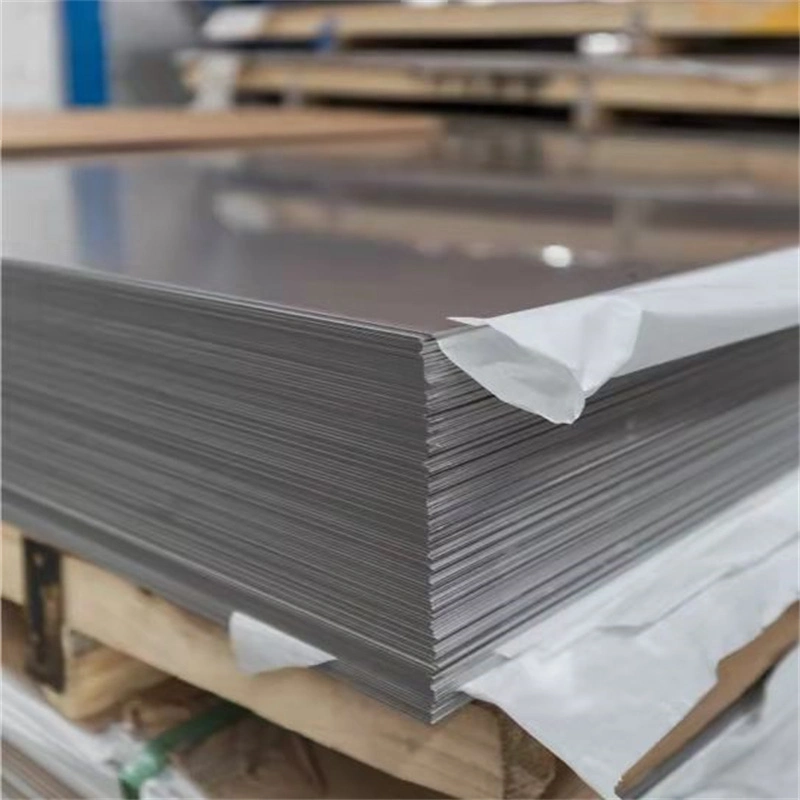

- Thickness: 0.2-200mm

- Width:10-2600mm

Description

3004 aluminum plate is a versatile alloy known for its excellent corrosion resistance and formability. As an AL-Mn series alloy, it is the most widely used rust-resistant aluminum with slightly higher strength than industrial pure aluminum. This non-heat-treatable plate is ideal for applications that require good weldability and high corrosion resistance, such as chemical equipment, fuel tanks, and a variety of sheet metal products. With a tensile strength range of 150 to 285 MPa and elongation up to 16%, our 3004 aluminum plate offers the perfect balance of strength and processability to meet your manufacturing needs.

| 3004 Aluminum Plate Parameters

| Product | 3004 Aluminum Plate |

| Temper | H12, H14, H16, H24, H26, H32, O, H112, T3, T6, T4, T651, ect. |

| Surface | Mill finish, color coated, embossed, engraving, checkered |

| Thickness | 0.2-200mm, or customize |

| Width | 10-2,600mm, or customize |

| Length | 100-100,000mm, or customize |

| Packing | Standard export packaging options include wooden boxes, or as specified |

| Payment | T/T, L/C 100% at sight |

| MOQ | Normally 5 tons, special require need discuss |

| Delivery time | 1-3 days for spot goods, 10-15 days for normal size, 15-25 days for special size |

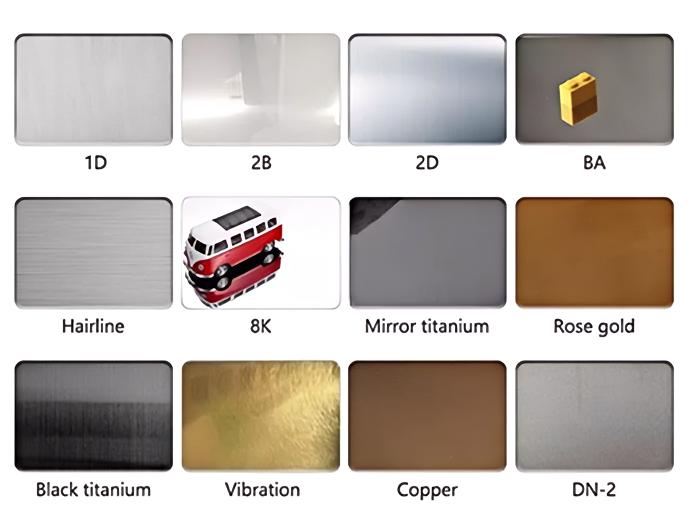

| Surface Treatment

| Chemical Composition of 3004 Aluminum Plate

| Element | Al | Si | Fe | Cu | Mn | Mg | Zn | Others Each |

| 3004 | Balance | ≤ 0.5% | ≤ 0.70% | 0.50 – 1.5% | 1.0 – 1.5% | 0.10 – 0.30% | ≤ 0.25% | ≤ 0.10% |

| Advantages of 3004 Aluminum Plate

- Moderate Strength: With manganese and magnesium content, the 3004 alloy has greater strength than pure aluminum, suitable for applications requiring moderate mechanical properties.

- Excellent Corrosion Resistance: The alloy’s composition provides good resistance to corrosion, making it durable for long-term use in various environments.

- Good Workability: The 3004 plate is easy to form and shape, allowing for complex fabrication processes such as deep drawing, bending, and stamping.

- Weldability: It has good weldability, which is crucial for applications that require the joining of metal pieces.

- Brazeability: The alloy’s brazeability makes it suitable for applications where high-temperature brazing is required.

- Recyclability: As with all aluminum alloys, the 3004 plate is fully recyclable, contributing to sustainability and reducing environmental impact.

- Cost-Effectiveness: The 3004 alloy offers a cost-effective solution for applications that require a balance of properties without the need for more expensive alloys.

- Thermal Conductivity: It provides good thermal conductivity, beneficial for applications involving heat transfer or dissipation.

- Aesthetics: The mill finish offers a clean, uniform appearance that is visually appealing for both functional and decorative uses.

- Versatility: The 3004 alloy is used in a wide range of applications, including transportation vehicles, shipbuilding, storage tanks, and general engineering structures, due to its versatility.

- Fabrication Compatibility: It is compatible with various fabrication processes, including machining, shearing, and punching, making it a versatile choice for manufacturers.

| Why Choose Us

- Innovative Custom Formulations: We don’t just offer standard aluminum products; we specialize in developing custom aluminum alloys tailored to specific industry needs, providing a solution that no other supplier can match.

- Sustainability Leadership: Our production processes are designed with sustainability in mind, from energy-efficient manufacturing to the use of recycled materials, positioning us as an industry leader in eco-friendly aluminum products.

- Exclusive Technology: We utilize proprietary technology that enhances the properties of our aluminum products, such as increased strength-to-weight ratios or unique surface treatments that offer superior resistance to environmental factors.

- Expert Consultation: Our team of experts provides unparalleled consultation services, working closely with customers to understand their unique challenges and offering tailored solutions that are unmatched in the market.

- Integrated Supply Chain Solutions: We offer a seamless, integrated supply chain solution that includes everything from raw material sourcing to finished product delivery, ensuring a level of convenience and efficiency that is unique in the industry.

- Advanced R&D Capabilities: With a state-of-the-art research and development facility, we are at the forefront of aluminum technology, constantly pushing the boundaries of what’s possible with our materials.

- Patented Processes: We have patented processes that give our aluminum products a distinct edge in terms of quality, performance, and applications, which cannot be replicated by competitors.

- Strategic Global Partnerships: Our strategic partnerships with key industry players provide customers with access to a network of resources and expertise that is unique to our company.

- Guaranteed Performance: We offer a performance guarantee on our aluminum products, ensuring customers that our materials will meet or exceed their expectations in real-world applications.

- Cultural Alignment and Ethical Practices: Our company operates with a strong ethical code and a culture that aligns with our customers’ values, building trust and a partnership that goes beyond mere transactions.

- Post-Sale Support and Education: We provide ongoing support and educational resources to help customers maximize the performance of our aluminum products, ensuring they get the most value from their investment.

- Exclusive Access to Niche Markets: We have established channels into niche markets that other suppliers cannot access, offering our customers unique opportunities for growth and expansion.

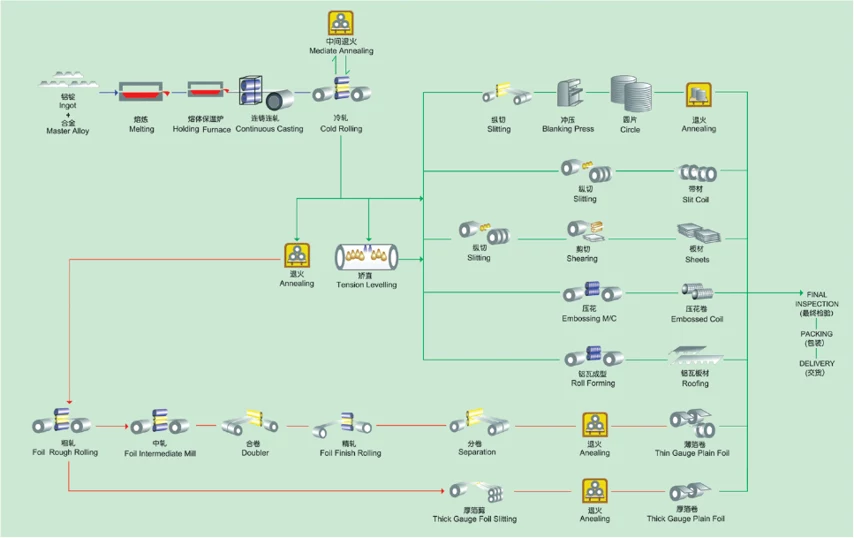

| process flow diagram

| Packaging and Shipping