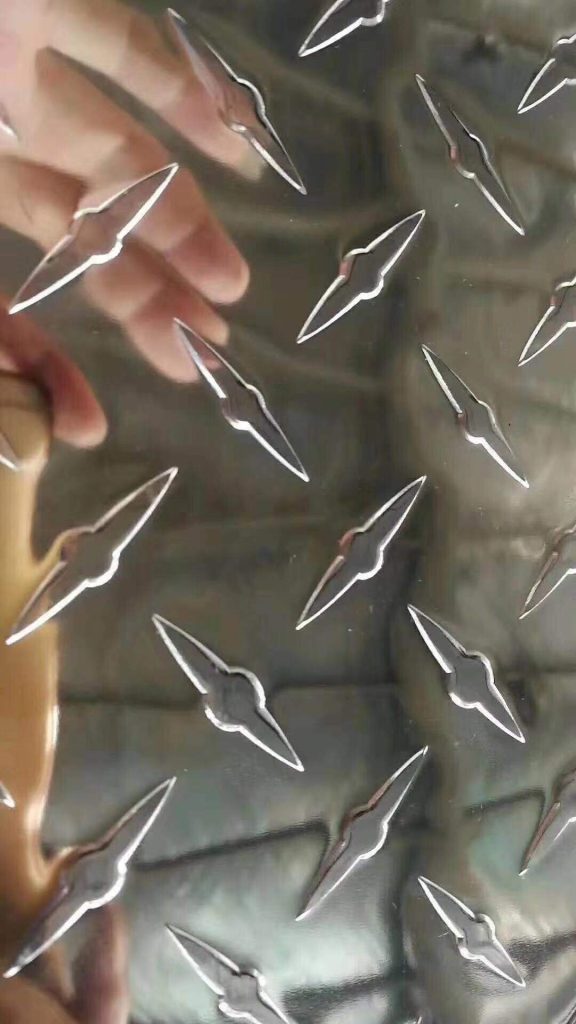

1200 Diamond Checkered Aluminum Plate

- Brand: DongChong

- Alloy: 1100, 1200, 1050, 1060, 3003, 3105 and 5052

- Temper: H12, H14, H16, H18, H22, H24, H26 and H28

- Thickness: 0.4mm to 8mm, or customize

- Width: 100-2000mm, or customize

- MOQ: 1 Ton

- Tolerance: ±1%

Description

| Checkered Aluminum Plate Parameters

| Product | Checker/Tread Aluminum Plate | |||||

| Materials | 1050, 1060, 1100, 1200, 3003, 3105, 5052 | |||||

| Temper | H12, H14, H16, H18, H22, H24, H26 and H28 | |||||

| Hole Types | Round hole, square hole, prismatic hole, triangular hole, pentagonal star hole, elongated hole, etc. | |||||

| Packing | Standard export packaging options include wooden boxes, or as specified. | |||||

| Payment | T/T, L/C 100%, Western Union | |||||

| Delivery Time | 1-3 days for spot goods, 10-15 days for normal size, 15-25 days for special size. | |||||

| Application | For non-slip floor in automobiles, airplanes, light rails, vehicle steps, stair treads, elevators, garages, workshops and more | |||||

| Available Dimension

| Mill Finish Surface | Bright Finish Surface | |

| Thickness (mm) | 1.00—6.50mm | 1.20—6.50mm |

| Pattern height | Sheet Thickness from 1.0mm to 2.0mm, bar height: 0.50mm | Sheet Thickness from 1.0mm to 2.0mm, bar height: 0.50mm |

| Sheet Thickness from 1.0mm to 2.0mm, bar height: 1.00mm | Sheet Thickness from 1.0mm to 2.0mm, bar height: 1.00mm | |

| Sheet Thickness above 2.0mm, bar height: 1.50mm | Sheet Thickness above 2.0mm, bar height: 1.50mm | |

| Width (mm) | Maximum 1500mm | Maximum 1650mm |

| Length (mm) | Maximum 6000mm | Maximum 6000mm |

| Paper interleaves | On request for selected | On request for selected |

| Normal size | 1200×2400mm, 1219×2438mm, 1219×3048mm | 1200×2400mm, 1219×2438mm, 1219×3048mm |

| Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al | |

| Each | Total | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | _ | 0.05 | 0.03 | 0.03 | _ | 99.6 |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | _ | 0.05 | 0.03 | 0.03 | _ | 99.5 |

| 1100 | Si+Fe:0.95 | 0.05-0.4 | 0.05 | _ | _ | _ | _ | 0.05 | 0.15 | 99 | |

| 1200 | Si+Fe:1.00 | 0.05 | 0.05 | _ | _ | 0.05 | 0.05 | 0.15 | 99 | ||

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | _ | _ | 0.1 | _ | 0.05 | 0.15 | R |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | _ | 0.25 | _ | 0.05 | 0.15 | R |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.1 | 0.25 | 0.1 | 0.05 | 0.15 | R |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | 0.4 | 0.1 | 0.05 | 0.15 | R |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | 0.25 | _ | 0.05 | 0.15 | R |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | _ | 0.05 | 0.15 | R |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | R |

| 5086 | 0.4 | 0.5 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | R |

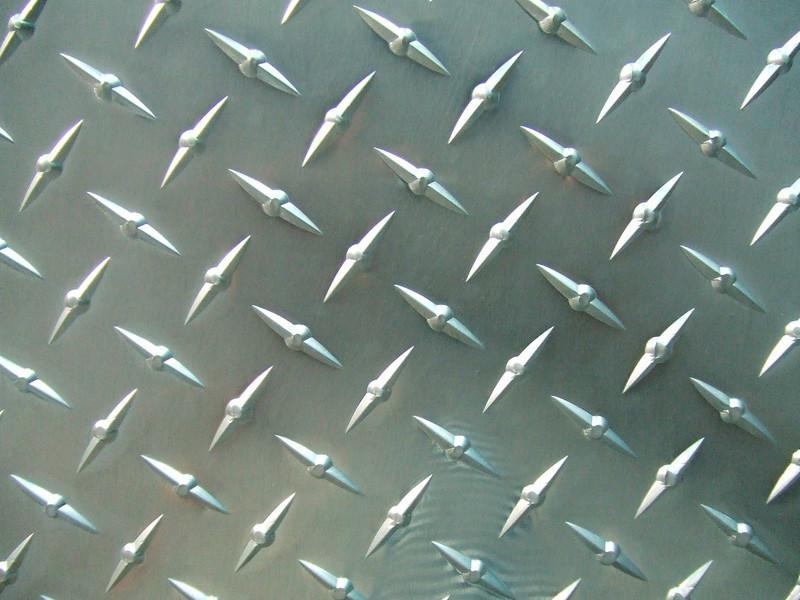

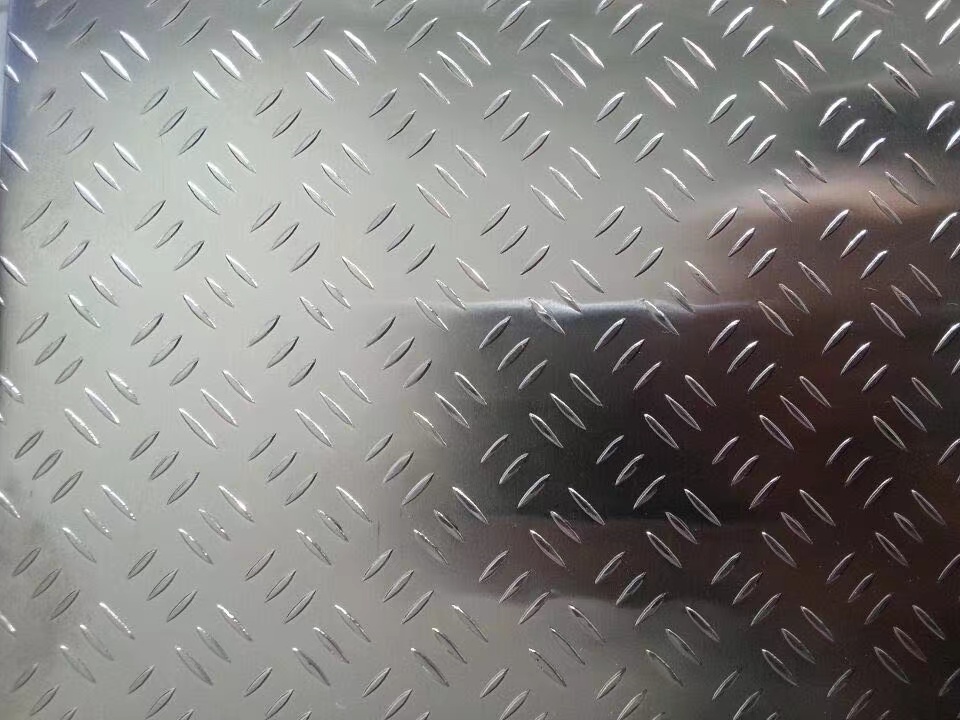

| According to Different Classifications

1. Ordinary Checkered Aluminum Plate:

An checkered aluminum plate processed from a 1060 aluminum plate base is suitable for general environments and is cost-effective. This type of patterned aluminum sheet is commonly used in cold storage, flooring, and outer packaging.

2. Aluminum Manganese Alloy Checkered Plate:

Made from 3003 as the primary material, this aluminum plate, also known as the anti-rust aluminum plate, has slightly greater strength than ordinary aluminum alloy checkered plates and offers some resistance to rust. However, its hardness and corrosion resistance are not as high as those of the 5000 series checkered plates. Therefore, this product is suitable for applications with less stringent anti-rust requirements, such as truck models and cold storage floors.

3. Aluminum Magnesium Alloy Checkered Plate:

Processed from 5000 series aluminum plates, such as 5052 or 5083, these plates offer excellent corrosion resistance, hardness, and rust prevention. Typically used in specialized settings like ships, carriage lights, and humid environments, this type of aluminum plate is known for its high hardness and considerable load-bearing capacity.

| Pattern of Checkered Aluminum Plate

| Advantages of Checkered Aluminum Plate

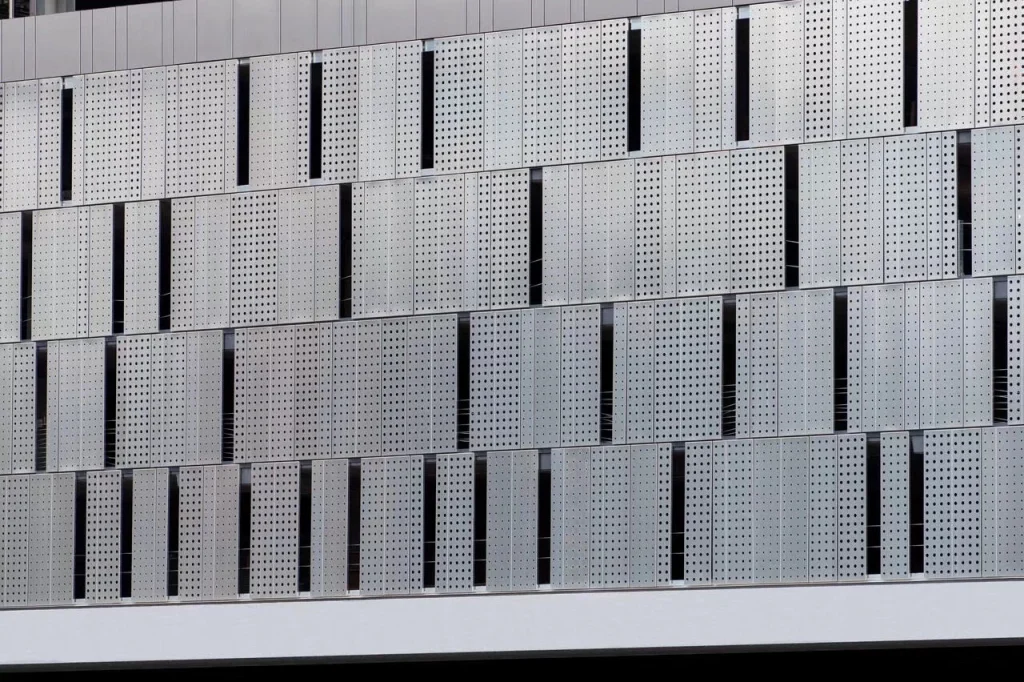

- Slip Resistance: The raised pattern on checkered aluminum plates provides excellent traction, making them ideal for use in areas where slip resistance is important, such as flooring, stair treads, and walkways.

- Durability: These plates are known for their strength and durability. The pattern adds to the rigidity of the plate, making it more resistant to wear and tear.

- Lightweight: Aluminum is inherently light, and patterned plates retain this property while offering other advantages. This makes them suitable for applications where weight is a concern.

- Corrosion Resistance: Aluminum naturally resists corrosion, and when it’s used in the manufacturing of checkered plates, this property is enhanced. Some aluminum alloys are further treated to improve their corrosion resistance.

- Cost-Effective: Compared to other materials with similar properties, checkered aluminum plates can be more economical, especially when considering their longevity and low maintenance requirements.

- Aesthetic Appeal: The pattern on the aluminum plate gives it a distinctive look that can be visually appealing in both industrial and decorative applications.

- Easy to Clean: The non-porous surface of checkered aluminum plates makes them easy to clean and maintain.

- Versatility: They can be used in a wide range of industries and applications, including construction, automotive, marine, and aviation, due to their strength, durability, and resistance to various environmental conditions.

- Recyclability: Aluminum is highly recyclable, which means that checkered aluminum plates can be recycled at the end of their service life, contributing to sustainability efforts.

- Customizability: The pattern, thickness, and sometimes even the color of checkered aluminum plates can be customized to meet specific application requirements.

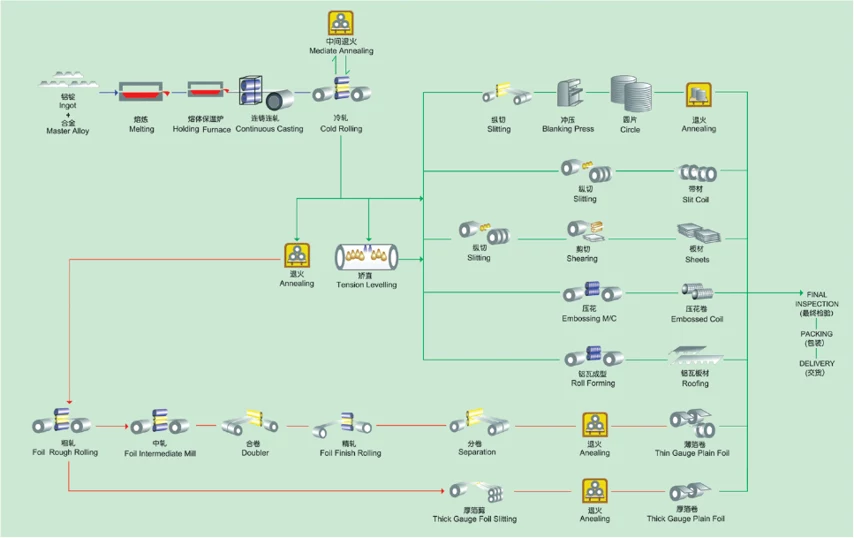

| process flow diagram

| FAQ

Q1. What is your terms of payment?

T/T 30% deposit in advance; the balance paid should be paid according to the copy of B/L.

Q2. What are the advantages of choosing DongChong as your checkered aluminum plate supplier?

We offer a wide range of products, advanced equipment, precise slitting tolerances, a large stock of materials, timely delivery, and professional, experienced staff.

Q3. How about your delivery time?

Generally, it will take 15 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings.

Q5. How can I customize the checkered aluminum plate to my specific requirements?

We provide one-stop service, including cutting, embossing, anodizing, and other processes to meet your exact specifications.

Q6. What quality control measures are in place during production?

We have a whole quality control system that includes raw material warehousing inspection, production and quality inspection, final product area and packaging, and after-sale management.

Q7. What are the after-sales services provided by DongChong?

We offer comprehensive after-sales services, including product quality certificates, ISO certifications, FDA approvals, and other relevant documentation.

Q8. How can I get the best quote?

Please provide DongChong’s expert team with the product specifications, dimensions, pattern style, purchase quantity, delivery address, contact information and other information you need, and our experts will provide you with one-to-one service.

| Packaging and Shipping