1070 Anodized Aluminum Coil

- Alloy: 1050, 1060, 1100, 1070, 3003, 3004, 3105, 5052, 5054, 5083, 6061, 6063, 6062, 7075, 8011

- Temper: H12, H14, H16, H24, H26, H32, O, H112, T3, T6, T4, T651, etc.

- Surface: Anodized

- Thickness: 0.1-6mm

- Width: 10-2600mm

- Inner core: 76/150/405/505mm

- MOQ: 300-500 KG

Description

| Specifications of 1070 Anodized Aluminum Coil

| Place of Origin | Chongqing, China |

| Brand | DongChong |

| Surface | Anodized |

| Thickness | 0.2-300mm or customized as required |

| Width | 10-3500mm or customized as required |

| Length | 2000mm, 2440mm, 6000mm or customized as required |

| Temper | O, H111, H112, H14, H18, H19, H22, H24, H26, H28, etc. |

| Standards | ASTM B209,JIS H4000 and etc. |

| Packing | Standard export packaging options include wooden boxes, or as specified |

| Tolerance | ±1% |

| Payment | T/T, 100%L/C, Western Union |

| Delivery Time | 1-3 days for spot goods, 10-15 days for normal size, 15-25 days for special size |

| Supply Ability | 30000T/per Month |

Mechanical Properties

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation Rate (%) |

| ≥75 | ≥35 | ≥ 4.5 |

Physical Performance

| Density | Melting Point | Modulus of Elasticity | Thermal Conductivity | Thermal Expansion |

| 2.7 Kg/m³ | 640 °C | 68 GPa | 230 w/m K | 23*10-6/K |

| Definition and Advantages of Anodizing

Definition

The process of using aluminum or aluminum alloy products as anodes, placing them in an electrolyte solution for energization treatment, and forming an aluminum oxide film on the surface by electrolysis is called anodization of aluminum and aluminum alloys.

Advantages

- Enhanced Corrosion Resistance: The anodic oxidation process forms a dense oxide film on the surface of the aluminum coil, significantly improving the material’s resistance to corrosion and enabling it to withstand erosion from a variety of chemicals.

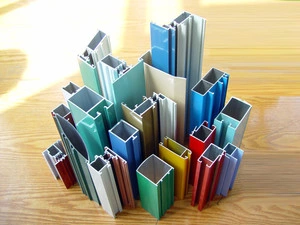

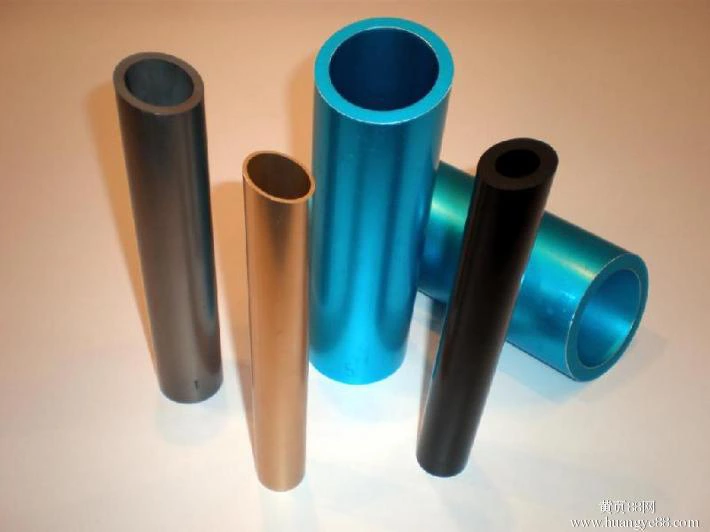

- Excellent Decorative Properties: Anodized aluminum coils can be colored in a variety of ways, providing a good decorative effect suitable for various design and architectural needs.

- Good Insulation Properties: The oxide aluminum film has good insulating properties, making anodized aluminum coil usable as an insulating material in electrical applications.

- Environmental Friendliness and Recyclability: The anodic oxidation process is an environmentally friendly surface treatment method, and anodized aluminum coils can be 100% recycled, reducing the impact on the environment.

- Easy Processing and Forming: Anodized aluminum coil maintains the good machinability of aluminum materials and can be easily processed by cutting, bending, and forming operations.

- Low Maintenance Cost: The maintenance cost of anodized aluminum coil is low, and the cleaning and maintenance process is simple, helping to reduce long-term operational costs.

- Good Weather Resistance: Anodized aluminum coil can resist ultraviolet radiation and is suitable for outdoor use, maintaining long-lasting aesthetics and performance.

| Equipment

Anodizing Pool

CNC Machines

| Anodizing Production Flow

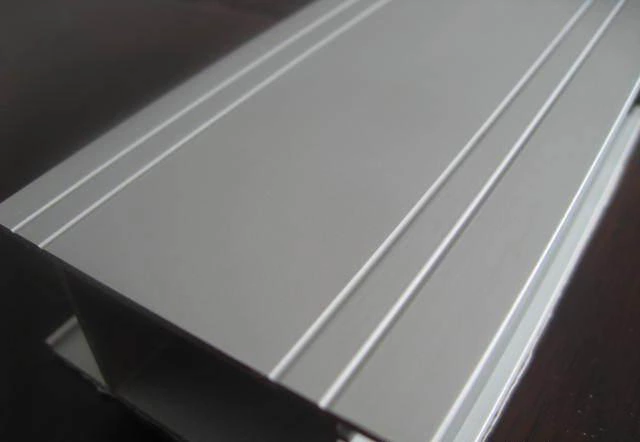

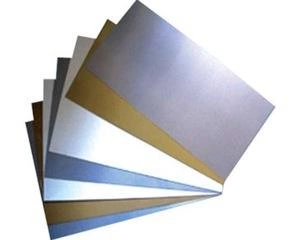

| Anodized Finished Product Photos

| Packaging and Shipping