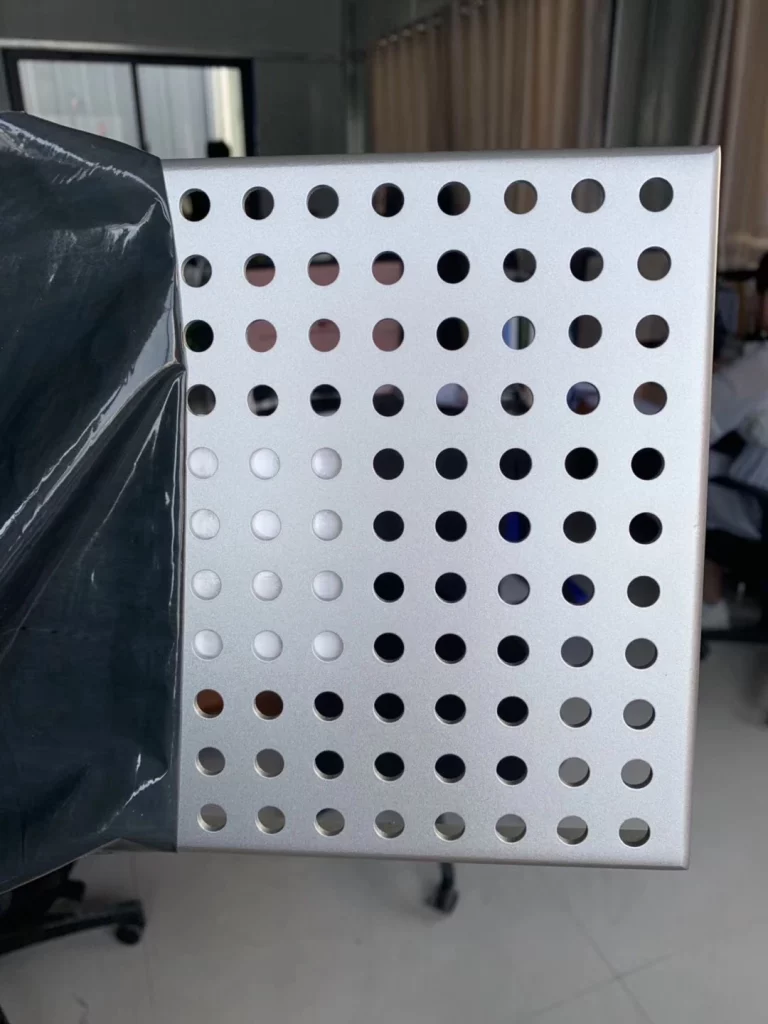

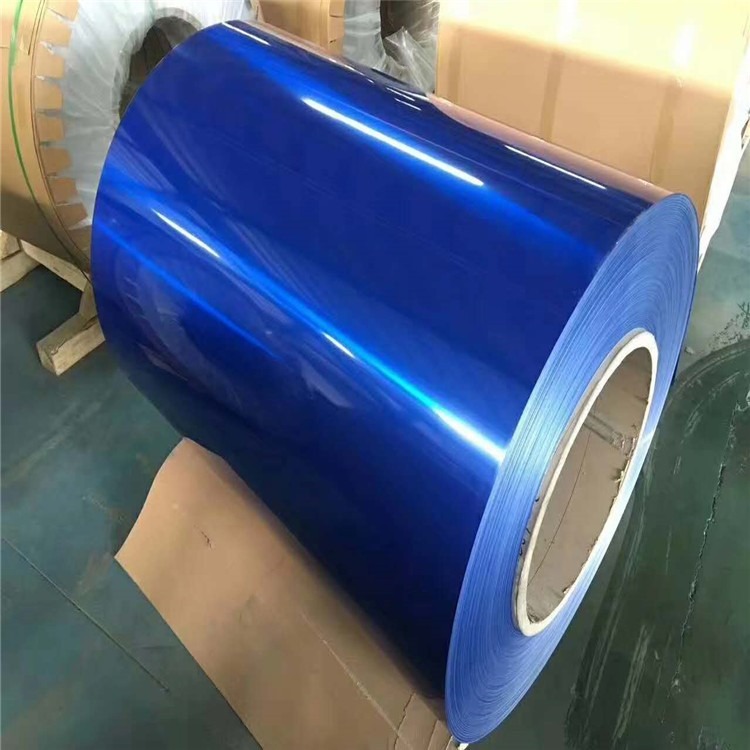

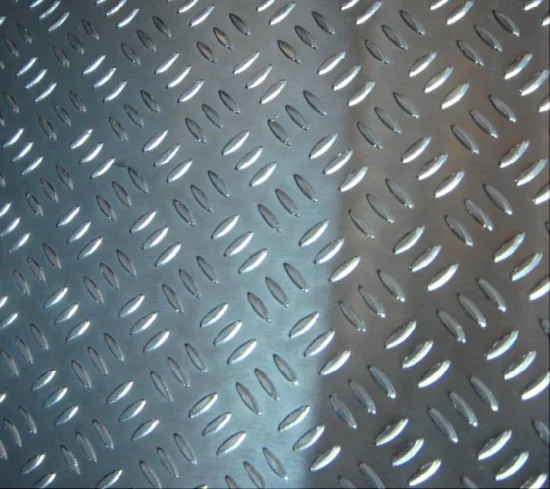

1060 Perforated Aluminum Plate

- Product: Perforated Aluminum Plate

- Alloy: 1060

- Temper: H12, H14, H16, H18, H24, H12, H22, H24, H32, H34, T6, T5

- Thickness: 0.2-10mm

- Width: 100-2000mm

- MOQ: 1 Ton

- Tolerance: ±1%

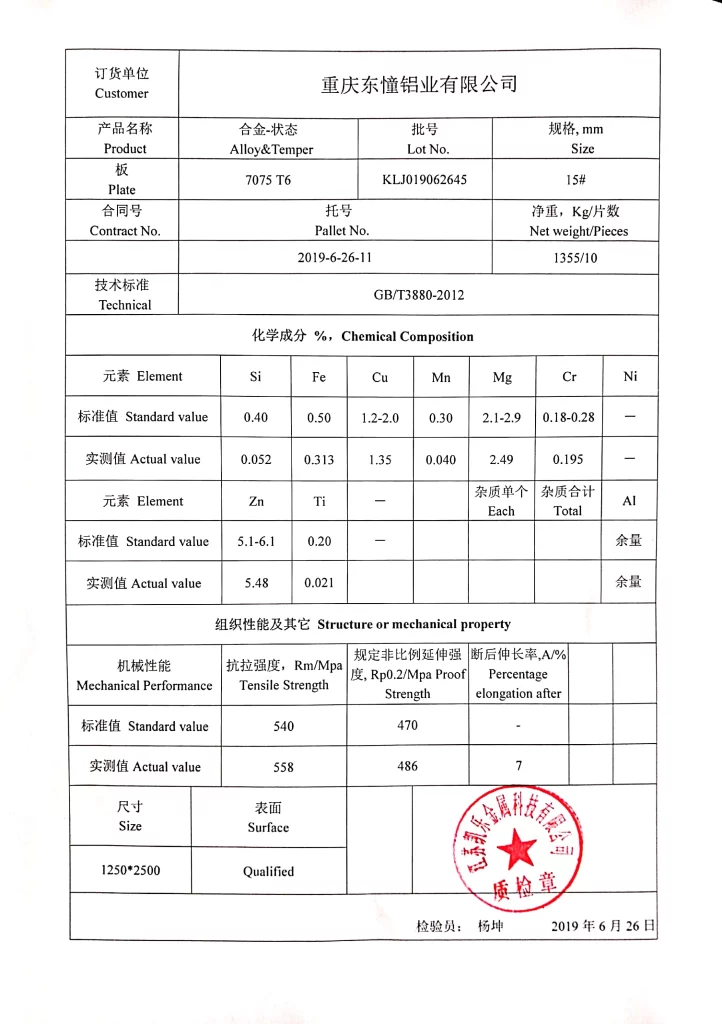

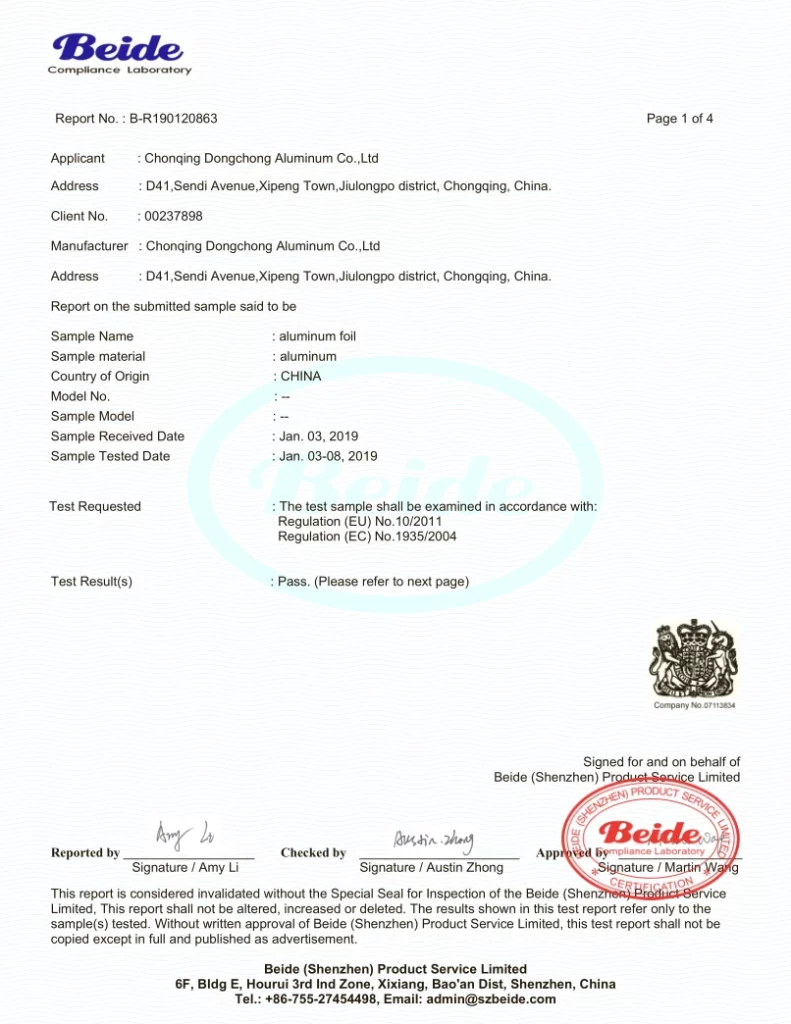

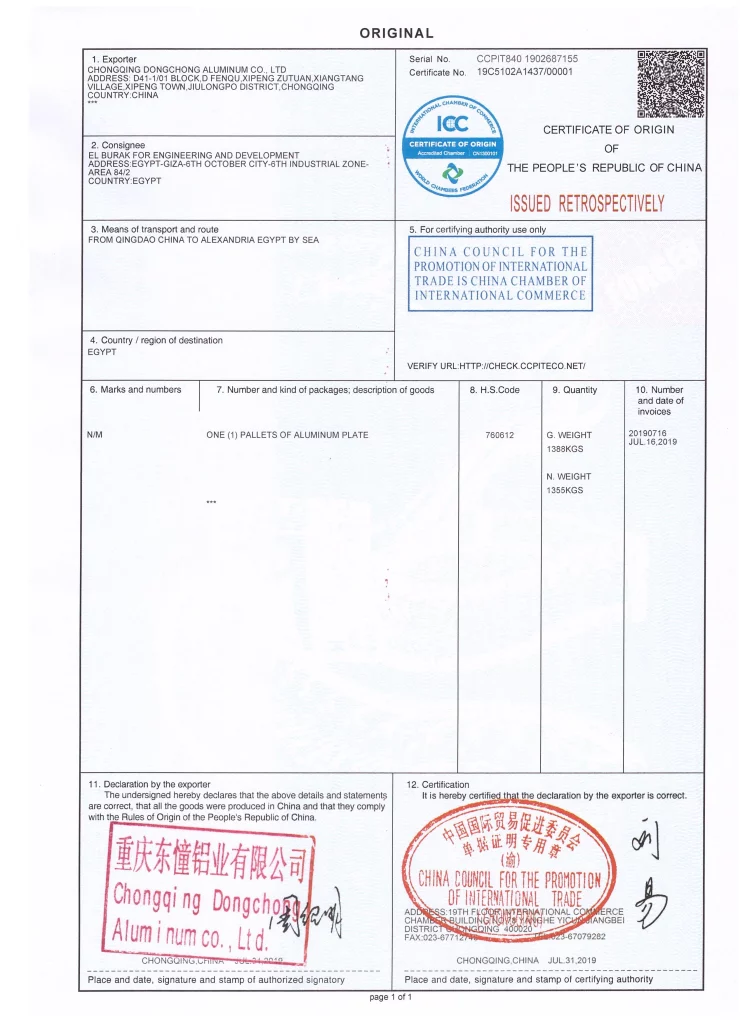

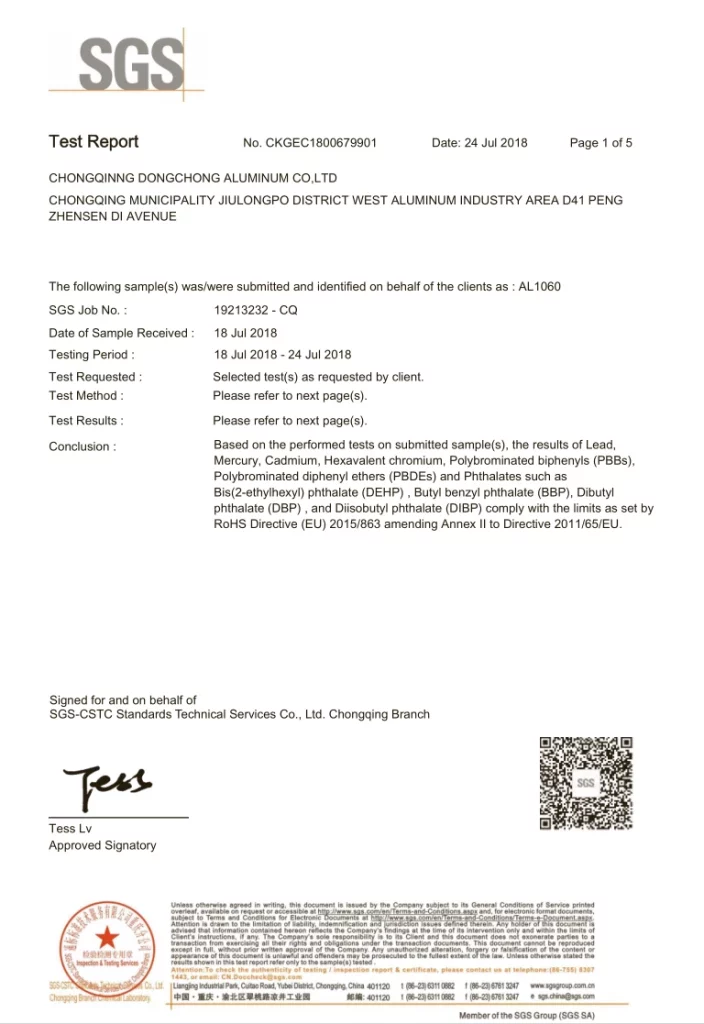

- Quality Control: Mill Test Certification is supplied with shipment,Third Part Inspection is acceptable.

Description

| Product performance

| Product | Perforated aluminum plate | |||||

| Materials | 1050 | |||||

| Process | Different metal plates are cut to suitable sizes and punched on CNC punching machines. | |||||

| Hole Types | Round hole, square hole, prismatic hole, triangular hole, pentagonal star hole, elongated hole, etc. | |||||

| Thickness | 0.2-10mm, or customize | |||||

| Width | 100-2000mm, or customize | |||||

| Length | 100-100,000mm, or customize | |||||

| Packing | Standard export packaging options include wooden boxes, or as specified. | |||||

| Payment | T/T, L/C 100%, Western Union | |||||

| Delivery Time | 1-3 days for spot goods, 10-15 days for normal size, 15-25 days for special size. | |||||

| Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM | |||||

| Perforated Aluminum Plate Features

- Versatility: Perforated aluminum plates can be used for various applications, from controlling airflow and sound to adding a decorative touch.

- Lightweight Strength: The holes reduce weight while maintaining the inherent strength of aluminum, making them ideal for architectural projects.

- Enhanced Airflow & Ventilation: Perforations allow for air, light, and sound to pass through, creating better ventilation and acoustic control.

- Visually Appealing Designs: Available in a wide range of hole patterns and sizes, perforated aluminum plates can add a modern and stylish touch to any project.

| Perforated Aluminum Plate Practical Purposes

- Ventilation and Airflow: Create efficient ventilation systems and airflow control with perforated aluminum plates, ideal for applications in HVAC systems, industrial equipment, and architectural screening.

- Lighting and Acoustics: Enhance lighting diffusion and acoustic performance in interior spaces with perforated aluminum plates, which can be used as decorative ceiling panels, wall cladding, and sound-absorbing elements.

- Filtration and Separation: Achieve precise filtration and separation of liquids and solids with perforated aluminum plates, perfect for industrial applications such as filtration screens, sieves, and strainers.

- Architectural Design: Elevate architectural design with custom-designed perforated aluminum plates, offering endless possibilities for creative expression in façade design, sunscreens, and decorative elements.

- Safety and Security: Enhance safety and security with perforated aluminum plates used in balustrades, barriers, and protective enclosures, providing both visibility and protection in public spaces.

Our perforated aluminum plates are available in a variety of patterns, hole sizes, and plate thicknesses to suit your specific requirements. Whether you’re an architect, designer, engineer, or manufacturer, our perforated aluminum plates offer unmatched versatility, durability, and aesthetic appeal for your projects.

Optimize the precision and efficiency of your fabrication needs with our Laser Cutting Aluminum Plate – the ultimate solution.

| Why Choose DongChong Perforated Aluminum Plate

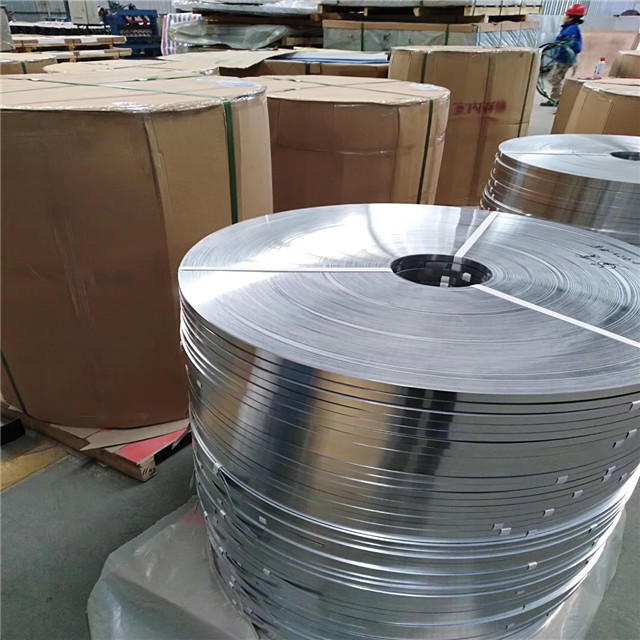

- Rich Product Line and Application Range: DongChong offers a variety of aluminum products, including aluminum plates, strips, foils, coils, pipes, rods, profiles, coated aluminum coils, curtain wall panels, decorative panels, corrugated panels, profiled panels, roof panels, and thermal insulation aluminum coils, etc., which are widely used in military industry, aerospace, electronics, electrical, machinery, chemicals, ships, transportation, automobile, building materials, and decoration, among other fields.

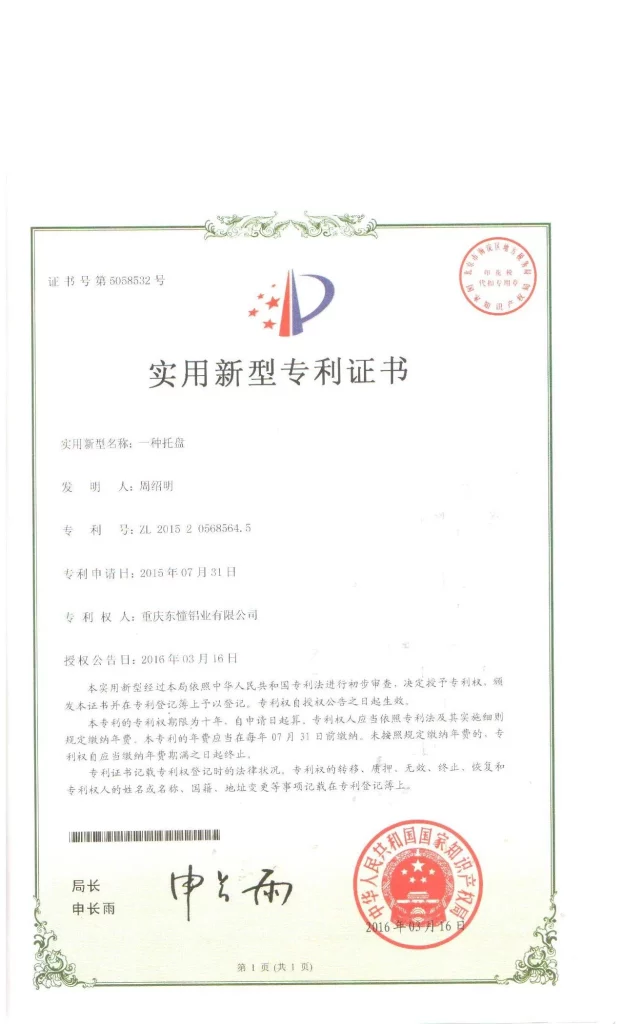

- Advanced Equipment and Technology: The company possesses advanced domestic aluminum coil leveling machines, slitting machines, aluminum foil slitting machines, CNC processing equipment, anodizing equipment, embossing machines, engraving machines, laser cutting machines, etc., capable of providing comprehensive aluminum processing products and services.

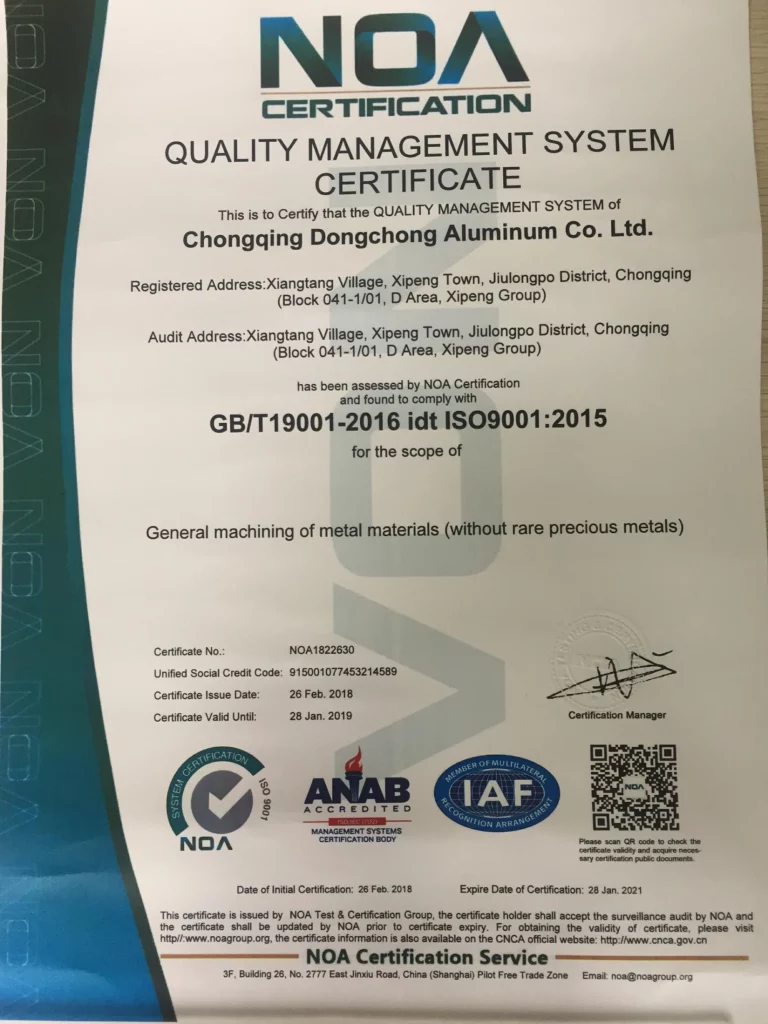

- Strict Quality Control System: DongChong implements a comprehensive quality management system, including raw material warehousing inspection, production and inspection, packaging, delivery, certification, loading into containers, and after-sales service, ensuring product quality and customer satisfaction.

- Strong Inventory Resources: The company has an inventory of 10,000 tons of various goods, capable of meeting the needs of different customers and ensuring timely supply.

- Timely Production and Delivery: DongChong promises to produce and deliver products in a timely manner after receiving the deposit, indicating the company’s focus on efficiency and customer time requirements.

- Professional Team: The main persons in charge of the company’s technical, production, and sales departments have more than 10 years of work experience, coming from state-owned or large-scale coastal enterprises, and have participated in many professional promotion trainings, ensuring high work efficiency and product quality.

- High-Quality Products and Services: DongChong provides one-stop services, solving the problem of customers looking for multiple suppliers, offering cost-effective products and the best quality services.

- Geographical Location Advantage: The company is located in the Aluminum Industrial Park of Chongqing, China’s “Aluminum Capital,” which may imply proximity to raw material supplies and a mature aluminum processing industry chain.

Contact us today for your aluminum plate laser cutting requirements and receive a complimentary quote.

We specialize in turning your designs into precise, functional products.

.