1060 Laser Cutting Aluminum Plate

- Product: Laser Cutting Aluminum Plate

- Alloy: 1060

- Temper: H12, H14, H16, H18, H24, H12, H22, H24, H32, H34, T6, T5

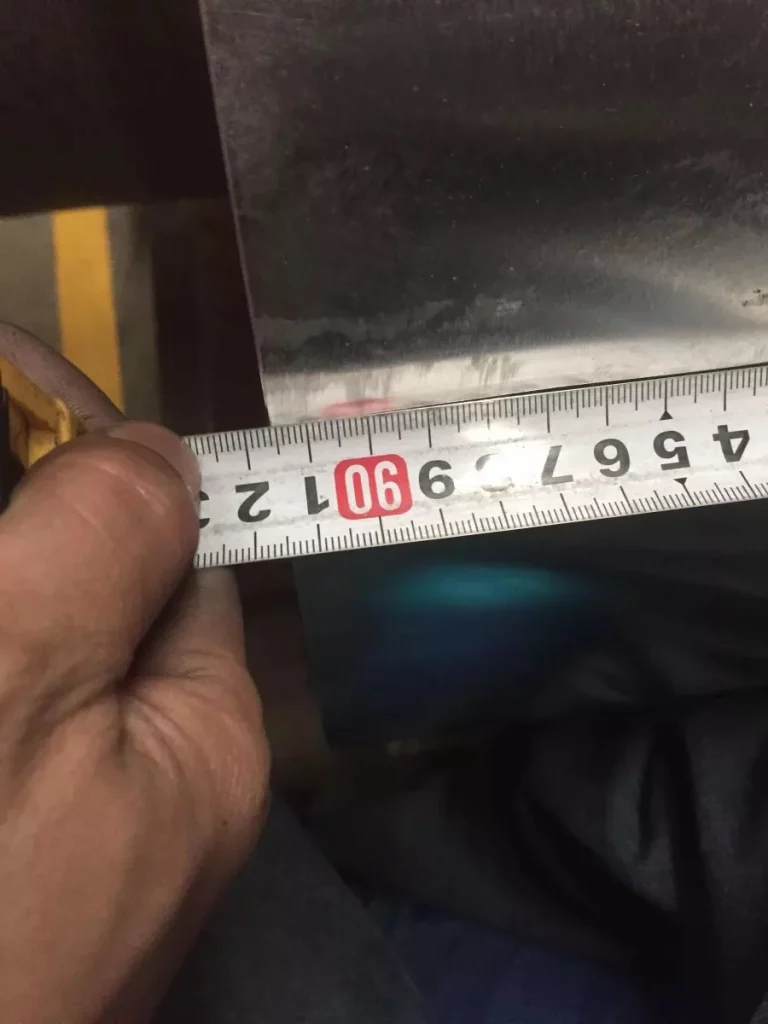

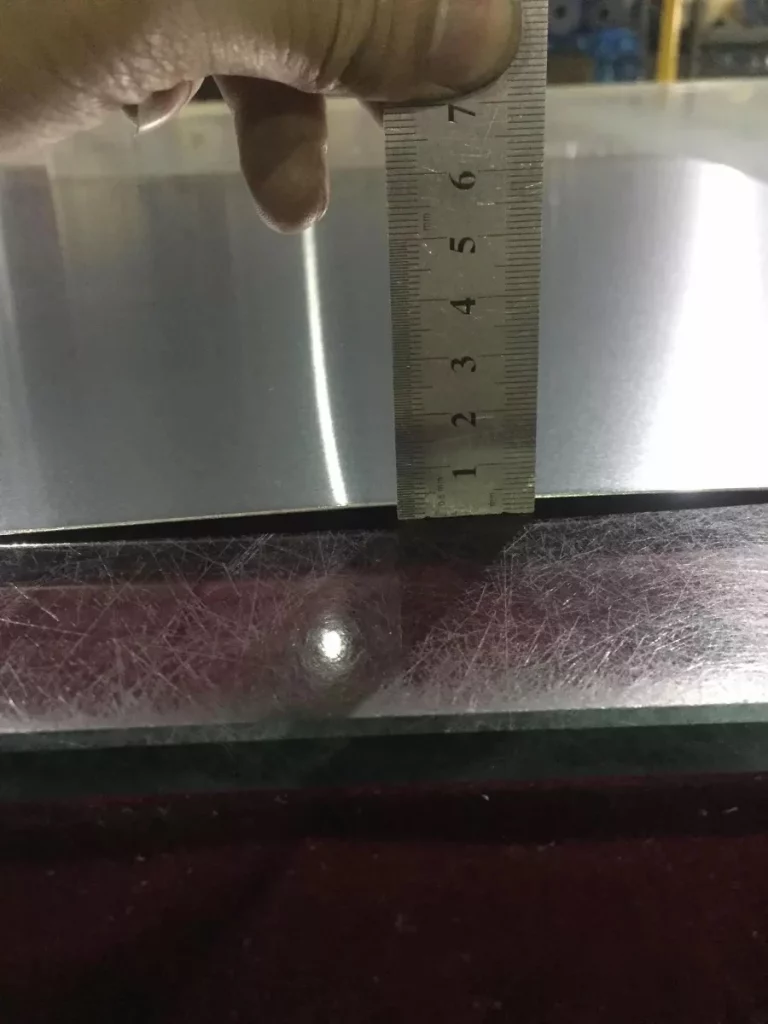

- Thickness: 0.2-10mm

- Width: 100-2000mm

- MOQ: 1 Ton

- Delivery time: 7-15 days within stock, special sizes require consultation

Description

| Specifications

| Product | Aluminum Plate | |||||

| Alloy | 1060 | |||||

| Technology | Laser Cutting | |||||

| Thickness | 0.2-300mm or customized as required | |||||

| Width | 10-3500mm or customized as required | |||||

| Length | 2000mm, 2440mm, 6000mm or customized as required | |||||

| Temper | O, H111, H112, H14, H18, H19, H22, H24, H26, H28, etc. | |||||

| Standards | ASTM B209, JIS H4000 and etc. | |||||

| Packing | Standard export packaging options include wooden boxes, or as specified | |||||

| Tolerance | ±1% | |||||

| Payment | T/T, 100%L/C, Western Union | |||||

| Introduction

Laser cutting of aluminum plates is a common process, especially in the metal processing and manufacturing industry. Laser cutting technology has significant advantages in accuracy, efficiency, and reliability, and can meet the processing needs of high quality, precision, and speed.

| The Advantages and Characteristics of Laser Cutting Technology

Laser cutting of aluminum plates is a physical process that relies on the thermal effect of a high-density laser beam to melt and evaporate metal materials, thereby achieving the cutting of metal materials. Laser cutting technology has the following advantages and characteristics:

- High precision and efficiency. Laser cutting technology has very high cutting accuracy and processing efficiency, which can meet various processing needs.

- Small heat-affected zone and small deformation. Laser cutting technology has a very small heat-affected zone and deformation, which can package processing accuracy and material performance.

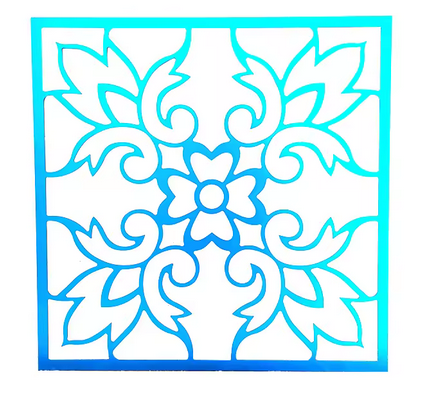

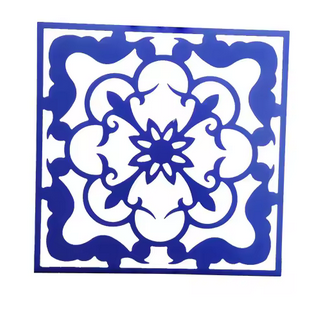

- Flexibility and diversity. Laser cutting technology can adapt to cutting various materials and shapes, with great flexibility and diversity.

- Environmental protection and energy conservation. Laser cutting technology is a very environmentally friendly and energy-saving processing method that can reduce waste and energy waste.

Generally speaking, the quality of laser cutting can be measured by the following six standards.

- Cutting surface roughness Rz

- Size of slag hanging on the incision

- Verticality and slope of the cut edge u

- Cutting edge fillet size r

- Stripe drag amount n

- Planarity F

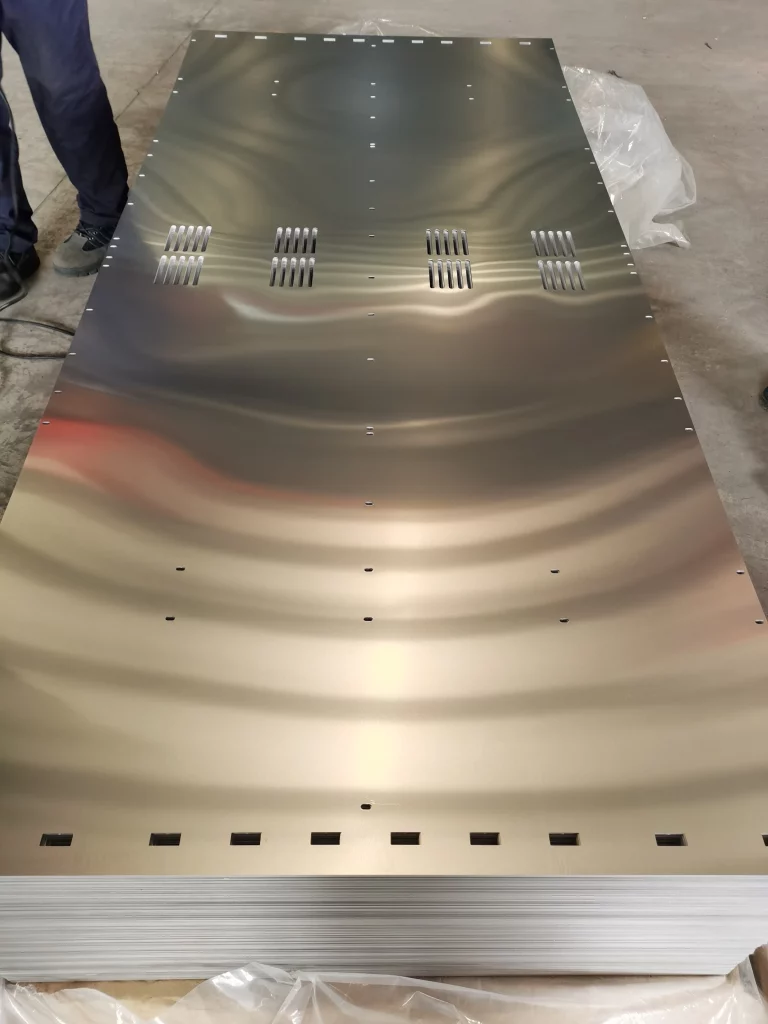

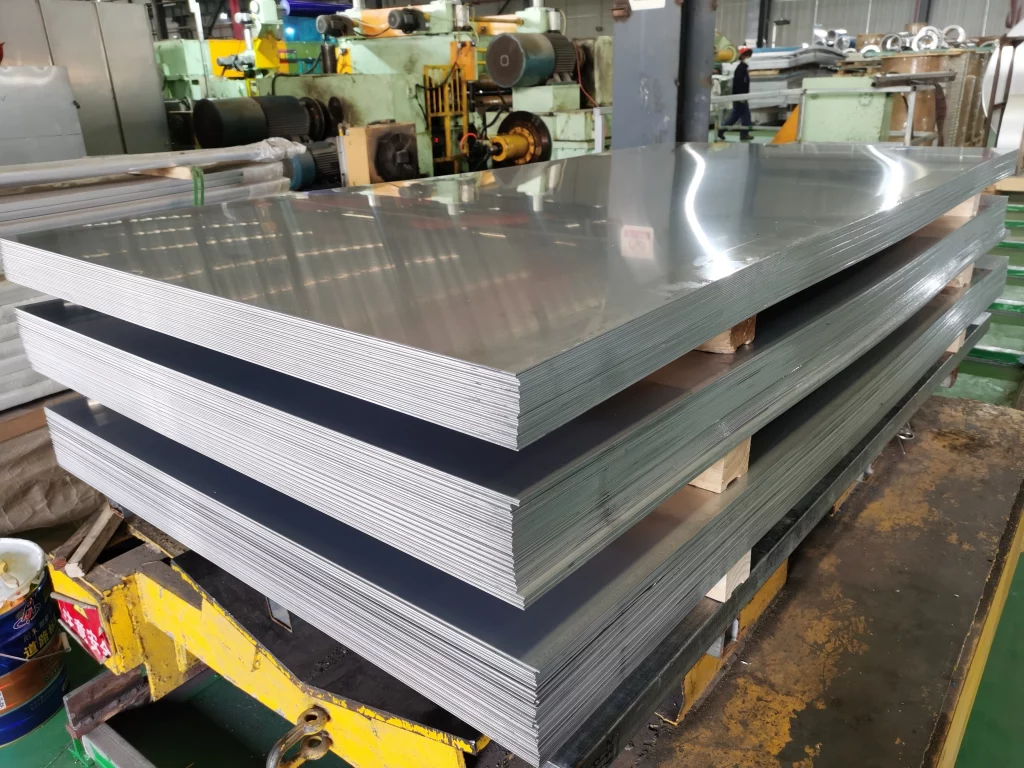

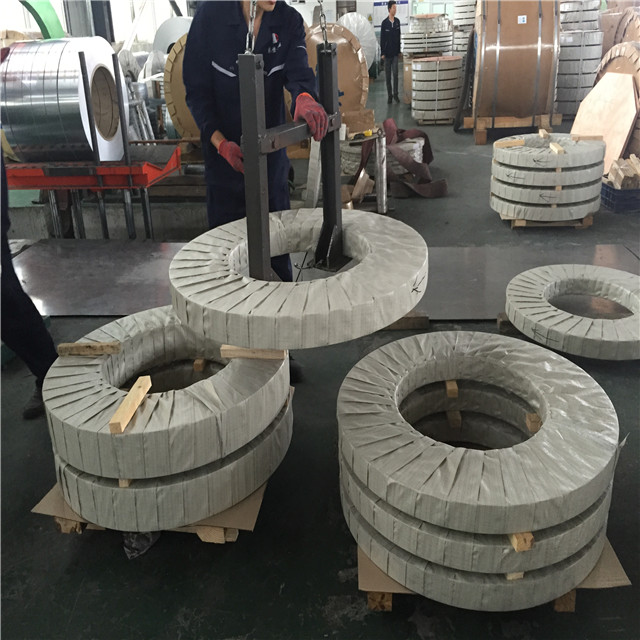

| Sample Display

| Key Features of DongChong Laser Cutting Aluminum Plate

- Precision Cutting: With laser accuracy down to the micron level, our aluminum plates are cut with unparalleled precision, ensuring tight tolerances and superior fitment for even the most demanding applications.

- Versatility: From simple shapes to intricate designs, our laser cutting process enables the fabrication of a wide range of geometries, making our aluminum plates suitable for diverse applications, including aerospace, automotive, electronics, and more.

- Speed and Efficiency: With high-speed laser cutting capabilities, we can quickly and efficiently process large volumes of aluminum plates, minimizing lead times and maximizing productivity for your projects.

- Clean Edges: Our laser cutting process produces clean, burr-free edges, eliminating the need for secondary finishing operations and reducing waste, saving you time and money in production.

- Customization: Whether you need standard sizes or custom dimensions, our laser cutting services can accommodate your specific requirements, allowing for limitless design possibilities and tailored solutions.

Experience the precision and efficiency of our Laser Cutting Aluminum Plate – the ultimate solution for your fabrication needs.

| Why Choose Chongqing DongChong

- Long Established: Established in 2002, DongChong Aluminum has over 20 years of industry experience, focusing on the research and development, production, and sales of various aluminum alloys.

- Rich Processing Experience: The company has accumulated extensive experience in the deep processing of aluminum products, capable of meeting customers’ demands for high precision and complex designs.

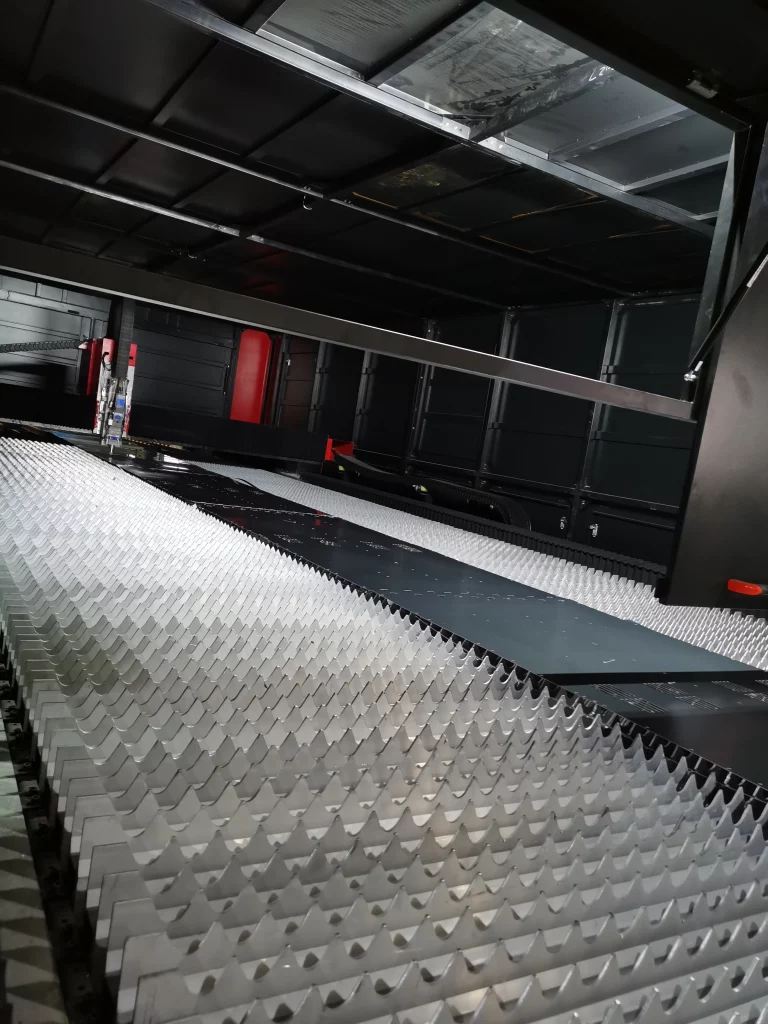

- Advanced Factory Equipment: The company is equipped with domestic and international advanced equipment such as aluminum coil leveling machines, slitting machines, aluminum foil slitting machines, CNC processing equipment, anodizing equipment, embossing machines, engraving machines, and laser cutting machines.

- High Processing Accuracy: These facilities ensure the precision and efficiency of the processing, thus providing high-quality laser-cut aluminum plates.

- Professional Team:DongChong Aluminum has a team of skilled technicians who ensure the accuracy and efficiency of the laser cutting process.

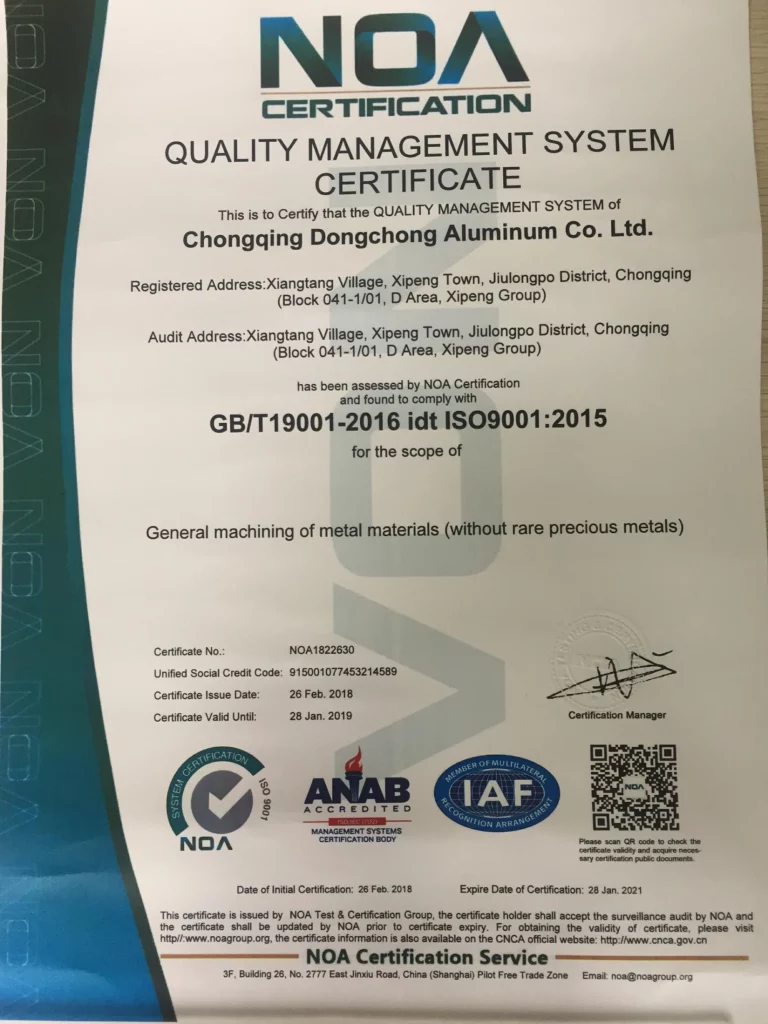

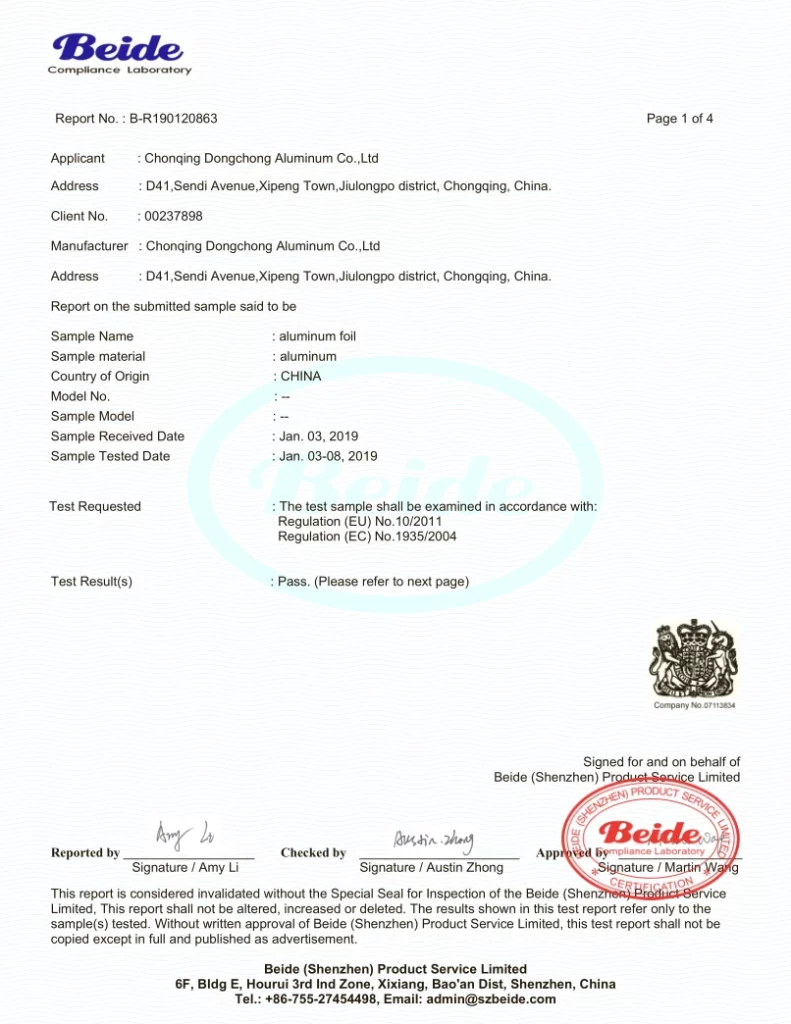

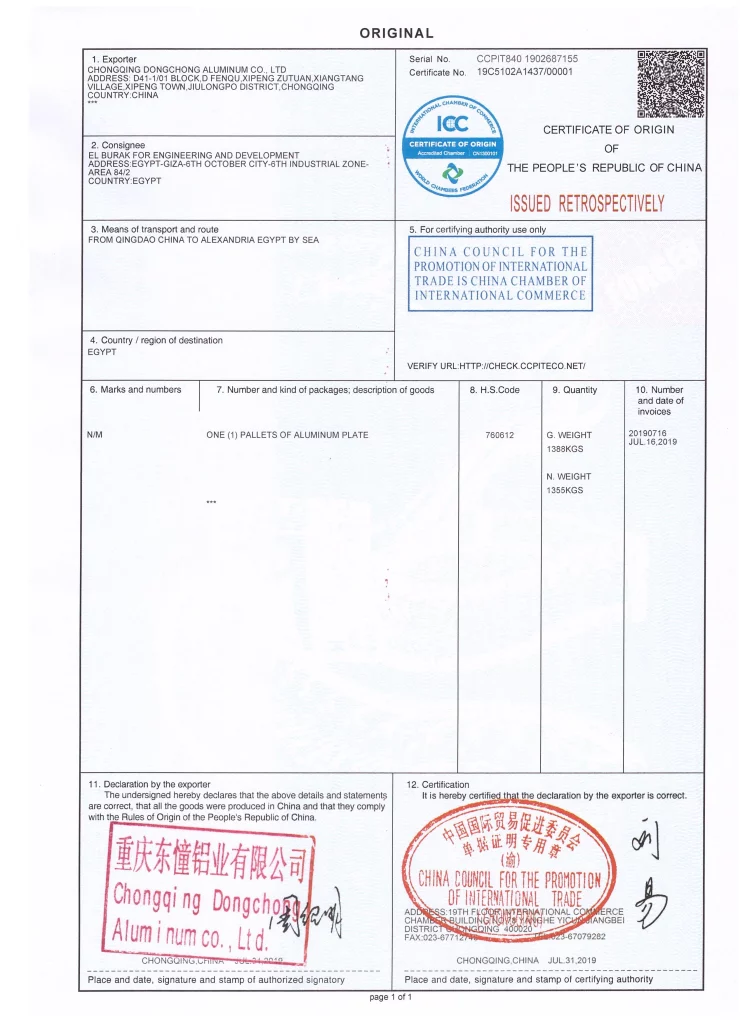

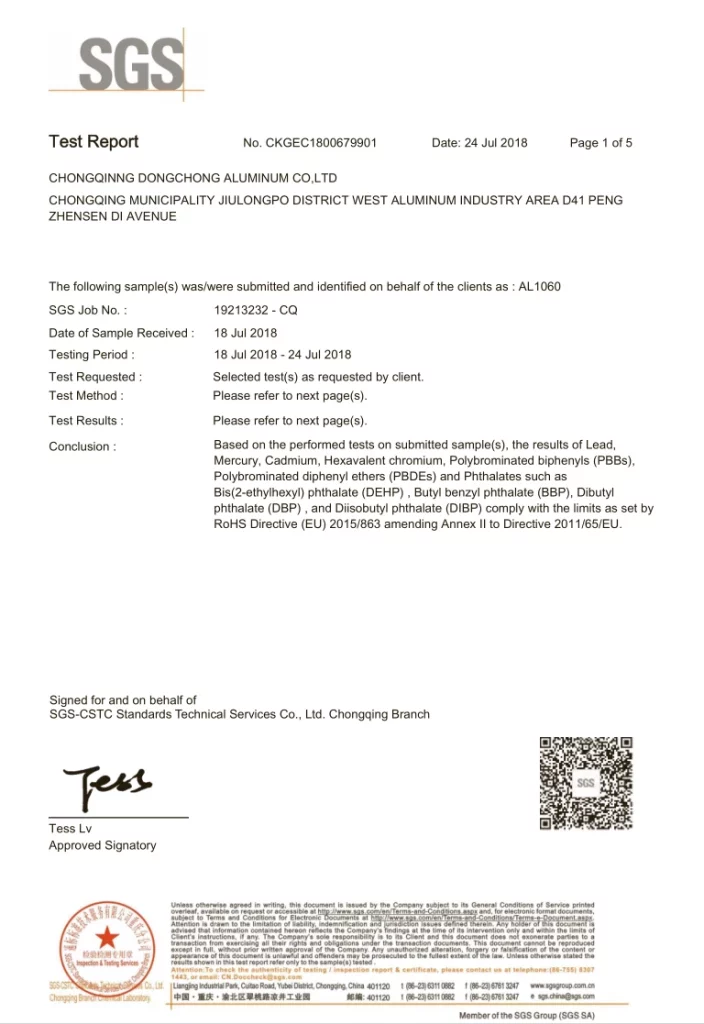

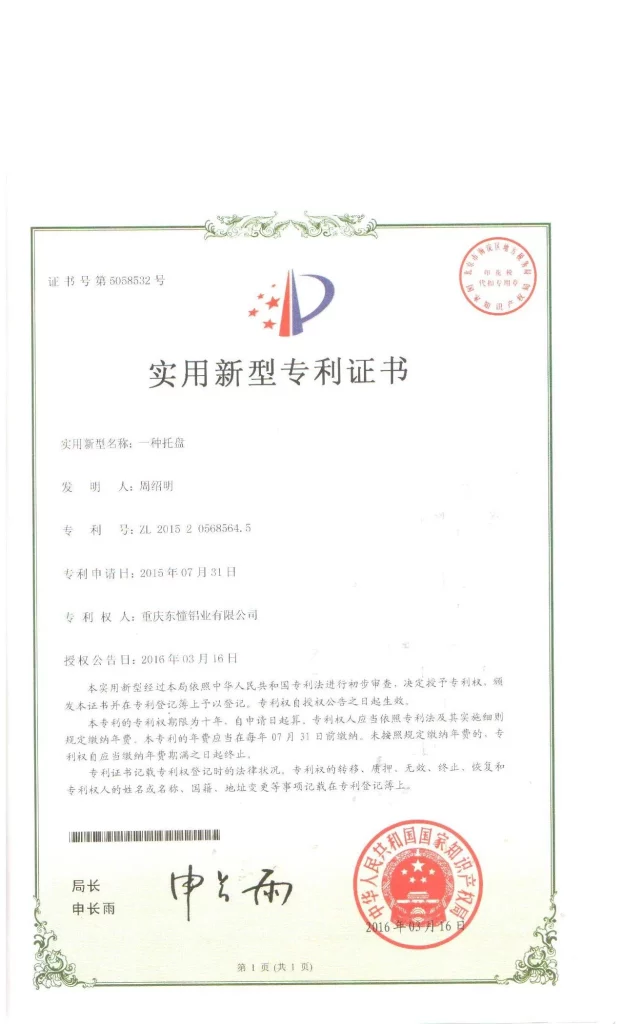

- Good After-sales Service: Our company has a professional after-sales service team that provides a comprehensive after-sales service package, including product quality assurance, ISO certification, FDA approval, certificate of origin, SGS report and patent certificate. Committed to ensuring our customers receive timely help and support throughout their product use, thereby increasing their satisfaction and building long-term relationships.

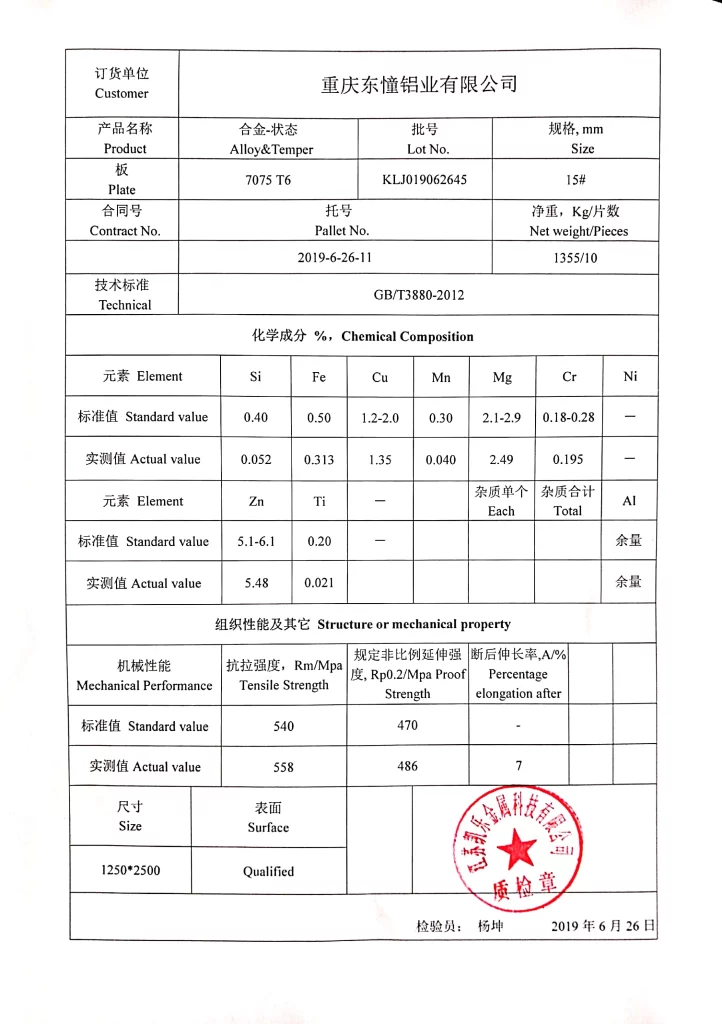

- Comprehensive Quality Management System: The company implements a complete quality control system, with strict quality checks at every stage from raw material storage inspection to finished product delivery. Production and quality tracking through an ERP system ensure that each product meets customer specifications.

- Diverse Products: DongChong Aluminum offers a variety of aluminum plate products, including aluminum alloy plates, strips, foils, coils, pipes, rods, profiles, coated aluminum coils, curtain wall panels, decorative panels, corrugated panels, profiled panels, roof panels, and thermal insulation aluminum coils.

- Customization Services: The company can provide customized laser cutting services according to customer needs, meeting the application requirements of different industries.

- Good Market Reputation:DongChong Aluminum’s products are highly recognized in the domestic market and are also exported to overseas countries, indicating that the company also enjoys a good reputation in the international market.