1050 Colored Aluminum Plate

- Brand: DongChong

- Alloy: 1100,1050, 1060, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 8011

- Temper: 0, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H42, H44, etc.

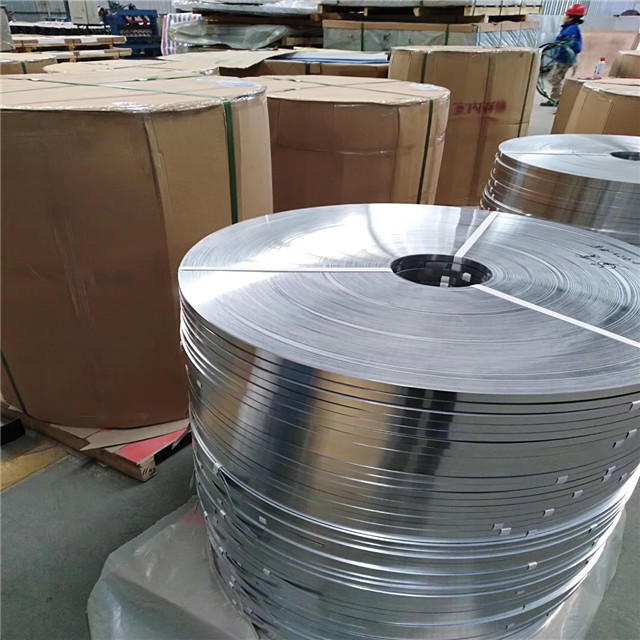

- Thickness: 0.024mm-1.20mm

- Width: 50mm-1700mm (Standard width: 914mm, 1000mm, 1219mm)

- MOQ: 500 spm

- Delivery Time: 7-15 days within stock, special sizes require consultation

- Tolerance: ±1%

- Payment: T/T, L/C 100%, Western Union

- Packing: Standard export packaging options include wooden boxes, or as specified.

Description

Colored aluminum plate is a decorative and protective metal material formed by coating one or more layers of organic coating on the surface of aluminum plate and then curing it after baking. It not only has the characteristics of aluminum such as light weight, high strength and corrosion resistance, but also has rich colors and good decorative effects due to the addition of coating.

| Product Performance

| Paint type | PVDF Polyester acrylate |

| Thickness | 0.024mm-1.20mm |

| Width | 50mm-1700mm(Standard width:914mm,1000mm,1219mm) |

| Coils Core Diameter | 150mm,405mm,505mm,508mm,510mm POLYESTER>=17 micron |

| Coating Thickness | PVDF >=25 micron |

| Gloss | 10-90% |

| Coating Hardness(pencil hardness) | More than 2H |

| Coating Adhesion | No lower than first grade |

| Impact Resistance | No cracking and peeling (50kg/cm, ASTM D-2794:1993) |

| SheetMEK Resistance | More than 100 times |

| Quality Control | Mill Test Certification is supplied with shipment,Third-party Inspection is acceptable. |

| Usage | Aluminum composite panel, ceiling, door and windows, electric appliance, etc. |

| Temper | 0, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H42, H44, etc. |

| Application | ACP, aluminum, ceilings, aluminum sheets, honeycomb panels and aluminum roofing, lighting decoration. Household electrical appliances, food package (such as pop can cover & ring, pull), furniture, ect. |

| Colored Aluminum Plate Features

- Diverse Color Options: They offer a wide range of color choices, including solid colors, metallic shades, wood grain finishes, and stone patterns, to meet various architectural and design requirements.

- Corrosion Resistance: The coating effectively isolates the aluminum from direct contact with the environment, enhancing its resistance to corrosion and weathering, thus extending its service life.

- Stain Resistance: The smooth surface of the coating makes it less prone to dust and dirt accumulation, making it easy to clean and maintain.

- Good Workability: Colored aluminum plates can be bent, cut, and stamped, making them suitable for various construction and industrial applications.

- Environmental Friendliness: The coating is free of harmful substances, making it an eco-friendly material. Additionally, the high recyclability of aluminum helps in resource conservation.

- Fire Resistance: Aluminum itself has good fire-resistant properties, and the coating, when treated specially, can further improve the material’s flame retardancy.

- Wide Application: They are used in building exteriors, roofing, interior decoration, signage, furniture, transportation vehicles, and more.

| Applications of Color Aluminum Plate

Commercial buildings

- Shopping Mall and Office Building Exteriors: Color-coated aluminum panels are often used for exterior decoration of shopping malls and office buildings, providing a modern and professional look. They can be designed in different colors and patterns to enhance the visual appeal of the building.

- Billboards and Signs: Due to the durability and easy processing characteristics of color-coated aluminum panels, they are often used to create large billboards and commercial signs that are not only durable but also colorful and can attract customers’ attention.

- Roof Systems: Color-coated aluminum panels are also used as roofing materials in commercial buildings, especially in places where lightweight and corrosion-resistant materials are required. They can be designed in different shapes and styles to suit the overall design of the building.

Residential

- Exterior Cladding: In residential buildings, color-coated aluminum sheets are used as exterior cladding, providing protection and enhancing the aesthetics of the home. They can be customized in a variety of colors and textures to match the style of the home and its surroundings.

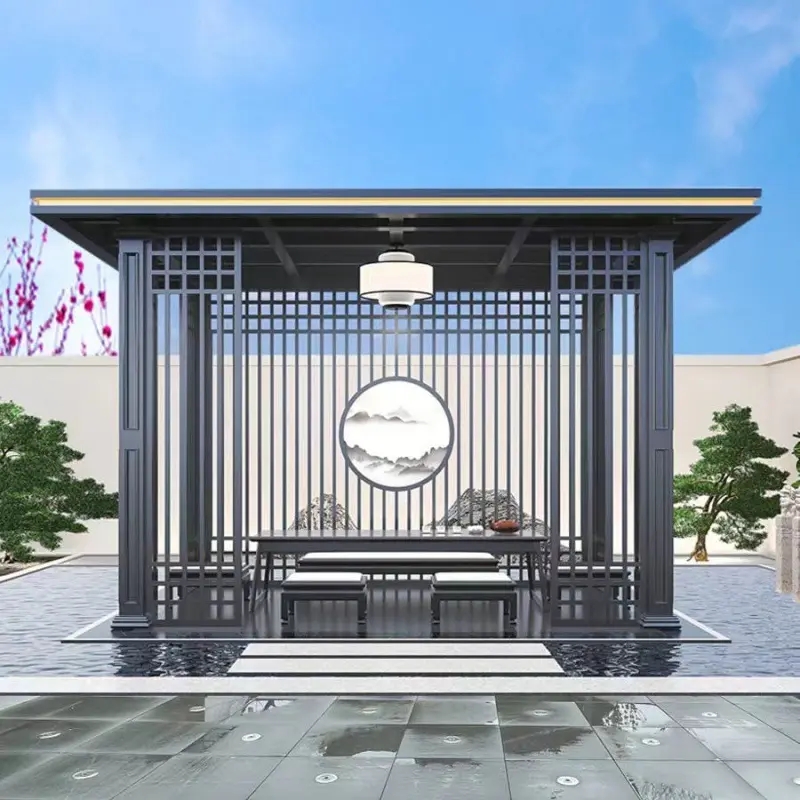

- Balconies and Gazebos: Color-coated aluminum sheets are often used in the construction of balconies and gazebos due to their corrosion and weather resistance, providing a durable and easy-to-maintain solution.

- Awnings and Sunshades: Color-coated aluminum sheets are also suitable for making awnings and sunshades, which not only provide necessary shelter but also enhance the appearance of the home.

Public Facilities

- Public Transportation Stations: Color-coated aluminum panels are used in the construction of public transportation stations such as bus stops and subway station entrances. They are not only durable, but also can enhance the visual effect of public spaces through different colors and designs.

- Stadiums and Exhibition Centers: Color-coated aluminum panels are often used on the exterior walls and roofs of these large public facilities because they can withstand large traffic and different climatic conditions.

- Parks and Recreational Areas: In parks and recreational areas, color-coated aluminum panels can be used to build pavilions, benches, trash cans and other facilities. They are not only beautiful but also easy to maintain.

- Schools and Educational Institutions: Color-coated aluminum panels are also suitable for architectural projects in schools and educational institutions, such as the exterior decoration of classrooms, libraries and administrative buildings, providing a durable and modern appearance.

| FAQ

Q1. What is the minimum order quantity?

Regular size color-coated aluminum sheet is 500 square meters. For special needs, please contact our experts for consultation.

Q2. What is your terms of payment?

T/T 30% deposit in advance; the balance paid should be paid according to the copy of B/L.

Q3. How about your delivery time?

Generally, it will take 15 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings.

Q5. Why can I trust you and place order with you?

We are manufacture and supplier of aluminum composite panel in china with over 22 year’s experience.We keep fastest delivery. Since we have perfect production equipment.

Q6. How can I get the best quote?

Please provide DongChong’s expert team with the product specifications, dimensions, purchase quantity, delivery address, contact information and other information you need, and our experts will provide you with one-to-one service.